Wie Sie sehen, transportieren Schiffe Millionen von Tonnen an Gütern rund um den Globus. Allerdings gibt es für jedes Schiff eine sichere Gewichtsgrenze; ein Schiff kann nicht unendlich viel Gewicht tragen. Wenn diese sichere Grenze überschritten wird, sinkt das Schiff und es kommt zu einem Unfall. Die Tragfähigkeit kann dabei helfen. Aber was ist die Tragfähigkeit (DWT) und warum ist sie so wichtig?

Auch wenn der Begriff komplex erscheint, hat er eine einfache und nützliche Bedeutung. Er hilft der Schifffahrtsindustrie bei der Messung und dem Ausgleich des Gewichts auf verschiedenen Schiffstypen. Wenn Sie mit dieser Terminologie nicht vertraut sind, machen Sie sich keine Sorgen! In diesem Artikel erkläre ich alles über DWT, ihre Bedeutung und die Faktoren, die sie beeinflussen. Fangen wir also an!

Was ist die Deadweight Tonnage?

Zunächst müssen wir verstehen, was die Tragfähigkeit ist.

Die Tragfähigkeit ist das maximale Gewicht, das ein Schiff sicher transportieren kann. Dazu gehören Ladung, Treibstoff, Wasser, Besatzung, Lebensmittel und alle anderen Vorräte. Die DWT umfasst jedoch nicht das Gewicht des Schiffes. Vereinfacht ausgedrückt ist die DWT das Gewicht, das ein leeres Schiff tragen kann, ohne dass die Gefahr des Untergangs besteht. Sie wird in metrischen Tonnen gemessen.

Die Tragfähigkeit gewährleistet, dass das Gewicht eines Schiffes innerhalb der sicheren Grenzen liegt. Angenommen, ein Schiff hat zu viel Gewicht, ohne seine DWT zu kennen, dann liegt es tief im Wasser. Dadurch erhöht sich das Risiko des Sinkens und von Unfällen. Daher müssen sich Schiffe an eine sichere DWT-Grenze halten, um sicher auf dem Meer zu fahren.

Außerdem assoziieren viele Menschen die DWT mit der Schiffsgröße. Dies ist jedoch ein Irrglaube. Wenn ein großes Schiff schwer ist, kann es eine kleinere DWT haben. Da ein kleines Schiff jedoch leichter ist, kann es mehr Gewicht tragen und eine höhere DWT haben. Wir können feststellen, dass die DWT nicht das Volumen oder den Raum eines Schiffes berücksichtigt, sondern nur sein Gewicht.

Bedeutung der Deadweight Tonnage

Die Tragfähigkeit ist von größter Bedeutung, da sie die Sicherheit des Schiffes auf See gewährleistet. Angenommen, ein das Schiff zu viel Gewicht hatt über die DWT-Grenze hinausgeht, steigt das Risiko von Schäden und Sinken. Erläutern wir, warum die Tragfähigkeit wichtig ist.

- Verhindert Überlastung: Wenn Sie die Belastungsgrenze Ihres Schiffes nicht kennen, beladen Sie es möglicherweise mit mehr Gewicht. Wenn ein Schiff über seine sichere Grenze hinaus belastet wird, liegt es zu tief im Wasser. Dadurch erhöht sich das Risiko des Sinkens. Wenn Sie jedoch die sichere Gewichtsgrenze (DWT) eines Schiffes kennen, können Sie es entsprechend beladen.

- Hilft bei der Frachtplanung: Bei der Frachtplanung geht es um die Bestimmung der maximalen Ladung, die ein Schiff befördern kann. Durch die Kenntnis der DWT können Frachtplaner die maximale Ladekapazität für jede Schiffsreise bestimmen. Auf diese Weise hilft die DWT den Frachtplanern, den gesamten Raum des Schiffes zu nutzen, ohne die sichere Gewichtsgrenze zu überschreiten.

- Verbessert die Kraftstoffeffizienz: Die Tragfähigkeit hat einen direkten Einfluss auf die Treibstoffeffizienz eines Schiffes. Wie das? Wenn ein Schiff entsprechend seiner sicheren DWT-Grenze beladen ist, fährt es reibungslos. Wenn das Schiff jedoch überladen ist, kann dies die Kraftstoffeffizienz des Schiffes beeinträchtigen.

- Unterstützt die Einhaltung von Rechtsvorschriften: Jedes Schiff, das in internationale Gewässer einfährt, muss die internationalen Schifffahrtsgesetze einhalten. Zu diesen Gesetzen gehört auch das maximale Frachtgewicht, das ein Schiff befördern kann (DWT). Wenn Sie die DWT Ihres Schiffes kennen, können Sie es sicher bis zu dieser Grenze beladen. Dies hilft Ihnen, die internationalen Schifffahrtsgesetze einzuhalten und sicher zu fahren.

- Hilft bei der Schiffskonstruktion: Beim Bau eines neuen Schiffes spielt die Tragfähigkeit eine entscheidende Rolle. Die Hersteller wissen zunächst, wie viel das Schiff insgesamt transportieren kann. Danach entwerfen sie das Schiff entsprechend dieser Gewichtsgrenze. Wenn ein Schiff beispielsweise mehr Ladung tragen muss, wird der Hersteller es dicker und stärker konstruieren. Ist die Tragfähigkeit jedoch geringer, wird das Schiff leichter konstruiert. Die DWT hilft auch bei der Auswahl der Maschinengröße und der Rumpfstärke.

DWT der verschiedenen Schiffstypen

Nicht jedes Schiff ist in der Lage, die gleiche Menge an Gewicht zu tragen. Vielmehr variiert die zulässige Tragfähigkeit (DWT) je nach Schiffstyp. Lassen Sie uns nun über die wichtigsten Schiffstypen und ihre DWT sprechen, wie in der folgenden Tabelle dargestellt.

| Schiffstyp | DWT Bereich (Tonnen) |

| Massengutfrachter | 10,000 - 150,000 |

| Containerschiff | 10,000 - 100,000 |

| Öltanker | 40,000 - 550,000 |

| Stückgutfrachter | Rund 25.000 |

| Passagierschiff | 1,000 - 100,000 |

Deadweight Tonnage vs. Lightweight Tonnage

Tragfähigkeit und Leichtgewicht sind zwei völlig verschiedene Dinge. Die Tragfähigkeit ist zum Beispiel das zusätzliche Gewicht, das ein Schiff auf dem Meer tragen kann. Bei diesem Gewicht kann es sich um Lebensmittel, Besatzung, Wasser, Treibstoff oder andere Dinge außer festen Teilen handeln. Die DWT gibt an, bis zu welcher sicheren Grenze Ihr Schiff ein Gewicht tragen kann.

Auf der anderen Seite ist die leichte Tonnage das tatsächliche Gewicht des Schiffes. Wenn ein Schiff leer ist oder kein externes Gewicht enthält, wird sein ursprüngliches Gewicht als Leichtgewichtstonnage bezeichnet. Die LWT umfasst hauptsächlich das Gewicht der festen Teile. So werden beispielsweise der Rumpf, die Maschinen, das Rohrleitungssystem, das elektrische System, der Propeller, die Ruder usw. zur Leichtgewichtstonnage gerechnet.

Kurz gesagt, bei der DWT geht es um die Tragfähigkeit eines Schiffes. Die LWT hingegen ist das Eigengewicht des Schiffes. Beide Maße zusammen helfen bei der Berechnung des Gesamtgewichts eines Schiffes unter Last. Das Gesamtgewicht eines Schiffes wird als Verdrängung bezeichnet. Wenn man die Leichtgewichtstonnage eines Schiffes zur Tragfähigkeit addiert, erhält man die Verdrängung des Schiffes.

Faktoren, die die Tragfähigkeit der Tonnage beeinflussen

Wie ich bereits sagte, ist die Tragfähigkeit für jedes Schiff spezifisch. Die DWT ist jedoch nicht für alle Bedingungen festgelegt. Mehrere interne und externe Faktoren können das Gewicht, das ein Schiff tragen kann, verändern. Lassen Sie uns also die Faktoren erörtern, die die Tragfähigkeit beeinflussen, um die Effizienz eines Schiffes zu gewährleisten.

1- Design und Größe eines Schiffes

Einer der wichtigsten Faktoren, die sich auf die Tragfähigkeit auswirken, ist die Konstruktion und Größe des Schiffes. Im Allgemeinen kann ein großes Schiff aufgrund seiner starken, dicken Konstruktion mehr Gewicht tragen. Ein kleines Schiff hat jedoch in der Regel eine geringere Tragfähigkeit, so dass es weniger Gewicht tragen kann, was jedoch nicht immer zutrifft. Zur Konstruktion eines Schiffes gehören auch das Stabilitätssystem und die Motorleistung. Wenn ein Schiff über einen reibungslosen, effizienten Motor verfügt, kann es seine Tragfähigkeit halten und einen sicheren Transport gewährleisten.

2- Zustand und Form des Schiffsrumpfes

Die Form und der Zustand des Schiffes sind das zweite Element, das die Tragfähigkeit des Schiffes beeinflusst. Wie? Nehmen wir an, der Rumpf eines Schiffes ist tiefer und breiter. Eine solche Rumpfform erhöht die Tragfähigkeit des Schiffes, da es höher schwimmen kann, ohne zu weit zu sinken. Andererseits liegt ein Schiff mit einem schmalen oder flachen Rumpf tief im Wasser, wodurch seine Tragfähigkeit sinkt.

In diesen Situationen kann sich das Risiko des Sinkens eines Schiffes durch übermäßiges Gewicht erhöhen. In ähnlicher Weise ist der Zustand des Schiffsrumpfes wichtig. Wie Sie wissen, kann der Rumpf mit der Zeit rosten und durch das salzige Meerwasser beschädigt werden. Ein korrodierter Rumpf senkt die DWT des Schiffes, da er seine Effizienz verringert.

3- Art und Dichte der Ladung

Die Art und Dichte der Ladung sind wichtige Faktoren, die sich auf die Tragfähigkeit eines Schiffes auswirken. Wie Sie wissen, ist die Tragfähigkeit das Gewicht der Fracht, die ein Schiff transportiert. Die Art der Ladung und ihr Gewicht wirken sich in erster Linie auf die Tragfähigkeit eines Schiffes aus. Ein dichteres Gut, wie Eisen, Kohle oder Erz, ist beispielsweise sehr schwer. Wenn Sie Gegenstände mit hoher Dichte auf ein Schiff laden, erreicht es schnell seine maximale Tragfähigkeit (DWT).

Das bedeutet, dass man nicht mehr Gegenstände auf ein Schiff laden kann, selbst wenn Platz vorhanden ist. Bei weniger dichten Materialien erhöht sich jedoch die Tragfähigkeit eines Schiffes. Sie können weniger dichte Materialien in großer Zahl auf ein Schiff laden. Auch die Art der Ladung hat einen Einfluss auf die Tragfähigkeit. Einige Ladungen, wie Flüssigkeiten und Chemikalien, erfordern eine besondere Handhabung und spezielle Container. Dies kann die Tragfähigkeit des Schiffes verringern.

4- Wetter- und Seebedingungen

Auch die Wetter- und Seebedingungen haben einen großen Einfluss auf das Gewicht, das ein Schiff transportieren kann (DWT). Wie das? Nehmen wir an, ein Schiff transportiert eine Ladung innerhalb seiner DWT-Grenze, aber plötzlich werden die Seebedingungen stürmisch und windig. Das Schiff könnte anfangen zu zittern. In einem solchen Fall muss das Schiff entladen werden, wodurch sich seine Tragfähigkeit verringert.

Wenn das Meerwasser kalt ist, wird es auch dichter. Dichteres Wasser erhöht den Auftrieb eines Schiffes und ermöglicht es ihm, mehr Gewicht zu tragen, wodurch sich seine Tragfähigkeit erhöht. Ist das Meerwasser jedoch heiß, nimmt seine Dichte ab, was den Auftrieb und die Tragfähigkeit (DWT) verringert.

5- Beschränkungen der Lastleitung

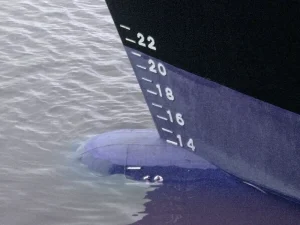

Eine Ladelinie ist eine Markierung auf dem Schiffsrumpf, die die sichere Tiefe angibt, in der ein Schiff bei voller Beladung sinken kann. Diese Linie stellt sicher, dass das Schiff keine schwere Last tragen kann und wirkt sich direkt auf die Tragfähigkeit aus. Wenn ein Schiff ein Gewicht trägt, das innerhalb seiner DWT liegt, aber die Ladelinie überschreitet (der Rumpf sinkt sehr tief ein), wird die DWT verringert.

Das bedeutet, dass man das Schiffsgewicht (DWT) senken muss, um eine sichere Ladelinie zu gewährleisten. Außerdem wird die Ladelinie, die sich direkt auf die DWT eines Schiffes auswirkt, sowohl durch heißes (weniger dichtes) als auch durch kaltes (dichteres) Salzwasser beeinflusst. So verbessert sich beispielsweise der Auftrieb eines Schiffes in kaltem Wasser, so dass es mehr Gewicht innerhalb einer sicheren Belastungsgrenze tragen kann.

6- Alter des Schiffes und seine Wartung

Auch das Alter des Schiffes, sein äußerer Zustand und die ordnungsgemäße Wartung beeinflussen die DWT. Wenn ein Schiff beispielsweise neu ist und im Laufe der Zeit ordnungsgemäß gewartet wird, kann es mehr Gewicht innerhalb seiner Tragfähigkeit befördern. Wenn ein Schiff jedoch zu alt ist und seine Teile beschädigt und korrodiert sind, verliert es seine Leistungsfähigkeit. Selbst wenn Sie das Schiff nun innerhalb seiner DWT-Grenze beladen, kann es diese Last nicht mehr bewältigen. Dadurch verringert sich die Gesamt-TWT eines Schiffes. Daher ist eine ordnungsgemäße Wartung, z. B. der Austausch verschlissener Teile, Schmierung usw., für die Erhaltung der Tragfähigkeit eines Schiffes von entscheidender Bedeutung.

Schlussfolgerung

Zusammenfassend lässt sich sagen, dass die DWT das Höchstgewicht ist, das ein Schiff sicher transportieren kann. Denken Sie daran, dass diese Last nicht das Gewicht des Schiffes, einschließlich der Motoren, des Rumpfes usw. umfasst. Es ist die maximale äußere Last, die ein Schiff sicher tragen kann, ohne zu sinken. Die Kenntnis der DWT ist für Frachtunternehmen sehr wichtig. Und warum? Weil sie ihnen hilft, ihr Schiff angemessen zu beladen und es nicht zu überladen, was zu Unfällen auf den Weltmeeren führen könnte. In einem solchen Fall würden die Unternehmen einen erheblichen Verlust erleiden. Vergessen Sie nicht, dass die DWT nicht immer für alle Bedingungen festgelegt ist. Sie kann von der Bauart des Schiffes, den Wetterbedingungen, dem Alter des Schiffes und der Beladungslinie beeinflusst werden.