オフショアパイプライン施工|工場直送

パイプ敷設用フロートの説明

パイプ敷設用フロートは、主に水中でのパイプライン敷設を補助するために使用される。パイプライン敷設用フロートを使用すると、パイプラインを制御された深さに浮かべることができます。フロートは、パイプラインが流れによって揺れるのを防ぎ、安定性を向上させる。このため、作業員がパイプラインを正しく配置することが容易になり、パイプラインを直接設置する場合に比べて、設置作業の難易度が大幅に下がる。パイプライン敷設用フロートは、浅瀬や潮の干満の差が激しい場所でのパイプライン敷設に特に適している。作業員は、パイプライン・フロートの間隔と浮力を調整して、パイプラインを適切に配置することができる。パイプライン敷設フロートは、パイプラインの浚渫、海底パイプラインの敷設、その他の沿岸建設プロジェクトで一般的に使用されている。パイプ敷設用フロートの設計は非常にシンプルですが、実際のプロジェクトでは重要な役割を果たします。.

お見積もり

Jerryborgは、お客様の特定の深さの要件を満たすために、様々なタイプのパイプライン敷設フロートを製造しています。当社のパイプライン敷設フロートには、3つの材料オプションがあります: スチール、ポリウレアコート、HDPE. .フロートは 独立気泡フォーム 様々な密度を持ち、耐久性に優れている。 ポリエチレンまたはポリウレタン・エラストマー・シェル. .さらに補強のために、ナイロン繊維の補強層を組み込むこともできる。.

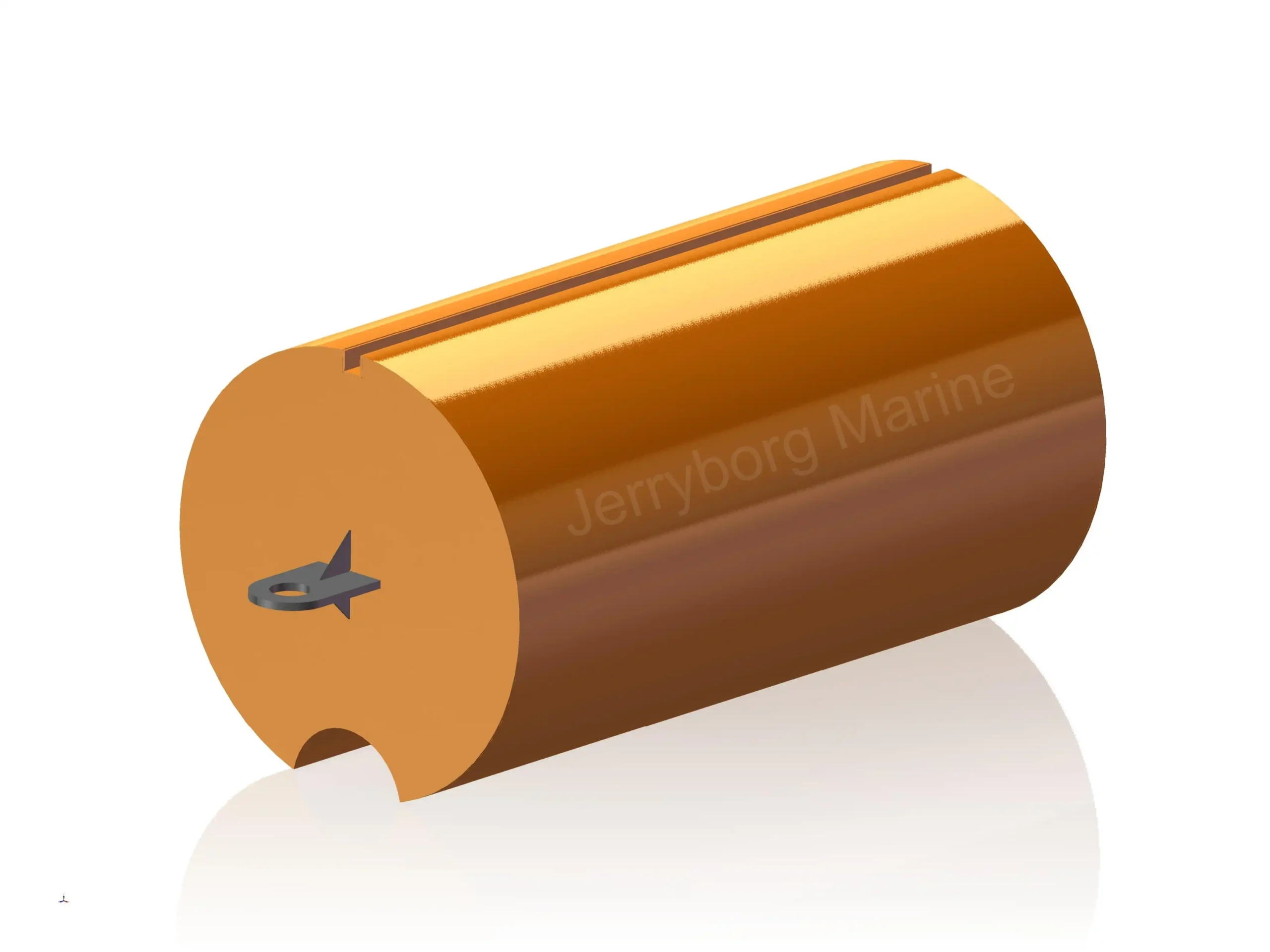

各パイプライン発泡ブイには、フロートをパイプにしっかりと固定するためのストラップ溝が組み込まれています。ジェリーボーグは、取り扱いと設置を簡素化するため、特注のエンドフィッティングを提供しています。お客様のニーズに応じて、ストラップやスチールケーブルなど、様々な固定方法でフロートをパイプに固定することができます。.

ジェリーボーグ海洋パイプ敷設フロートの利点

フォーム・ボディ

当社のパイプ敷設用フロートは、内部に独立気泡のポリエチレンフォームを使用しています。この発泡体は水を吸収しないため、水中で長時間使用しても浮力が低下することはありません。.

外側の保護デザイン

フロートはポリウレタンエラストマーでコーティングされている。使用中の衝撃は避けられませんが、ポリウレタンエラストマーコーティングが優れた保護効果を発揮します。.

強化構造層

パイプ敷設用フロートの補強層としてナイロンメッシュを追加することもできます。ナイロン補強により、破れる心配が少なくなります。.

柔軟な浮力構成

当社のフロートは柔軟に構成可能であり、泡の密度は顧客の特定のプロジェクトに応じて調整することができます。異なる密度のパイプ敷設用フロートは、異なる水深に適しています。.

サイズ調整可能

フロート下部の溝はパイプサイズに合わせて調整可能です。これにより、フロートは異なるパイプ仕様に適合し、取り付けが容易になります。.

カスタマイズ可

ジェリーボーグマリンではカスタマイズのご要望を承っております。フロートのサイズ、浮力、構造など特別なご要望があれば、お客様の用途に合わせてカスタマイズいたします。.

仕様

フロートをパイプに最適に設置するため、ジェリーボーグ・マリン社は、さまざまなパイプ径や水深に対応するパイプ敷設用フロートを設計しています。当社のパイプ敷設用フロートは、パイプの曲率に完全に一致するよう、底部に湾曲した溝を備えています。内部の発泡材や表面材が異なるため、パイプ敷設用フロートの重量や浮力が異なる場合があります。下記は一般的に使用されているパイプ敷設用フロートの寸法です。.

お問い合わせ|

モデル |

幅(mm) |

高さ (mm) |

長さ (mm) |

|

PLF 2500 |

800 |

900 |

2500 |

|

PLF 3000 |

1000 |

900 |

3000 |

|

PLF 1100 |

1100 |

1100 |

1100 |

|

PLF 1200 |

1100 |

1100 |

1200 |

|

PLF 1400 |

1100 |

1100 |

1400 |

|

PLF 2400 |

1100 |

1100 |

2400 |

|

PLF 3600 |

1100 |

1100 |

3600 |

|

PLF 4800 |

1100 |

1100 |

4800 |