제리보그 마린 에어백

선박용 고무 에어백은 통나무 압연 방식을 기반으로 하며, 리프팅과 베어링에 부드러운 고무를 사용합니다. 중국에서 독립적인 지적 재산권을 가진 혁신적인 제품입니다. 그것은 무거운 리프팅, 선박 발사 및 업그레이드, 케이슨 리프팅 및 수중 엔지니어링 부력 보조 분야에서 널리 사용됩니다. 해양 고무 에어백은 공간과 중장비의 제약을받지 않으므로 건설 기간을 효과적으로 단축하고 많은 비용을 절약 할 수 있습니다.

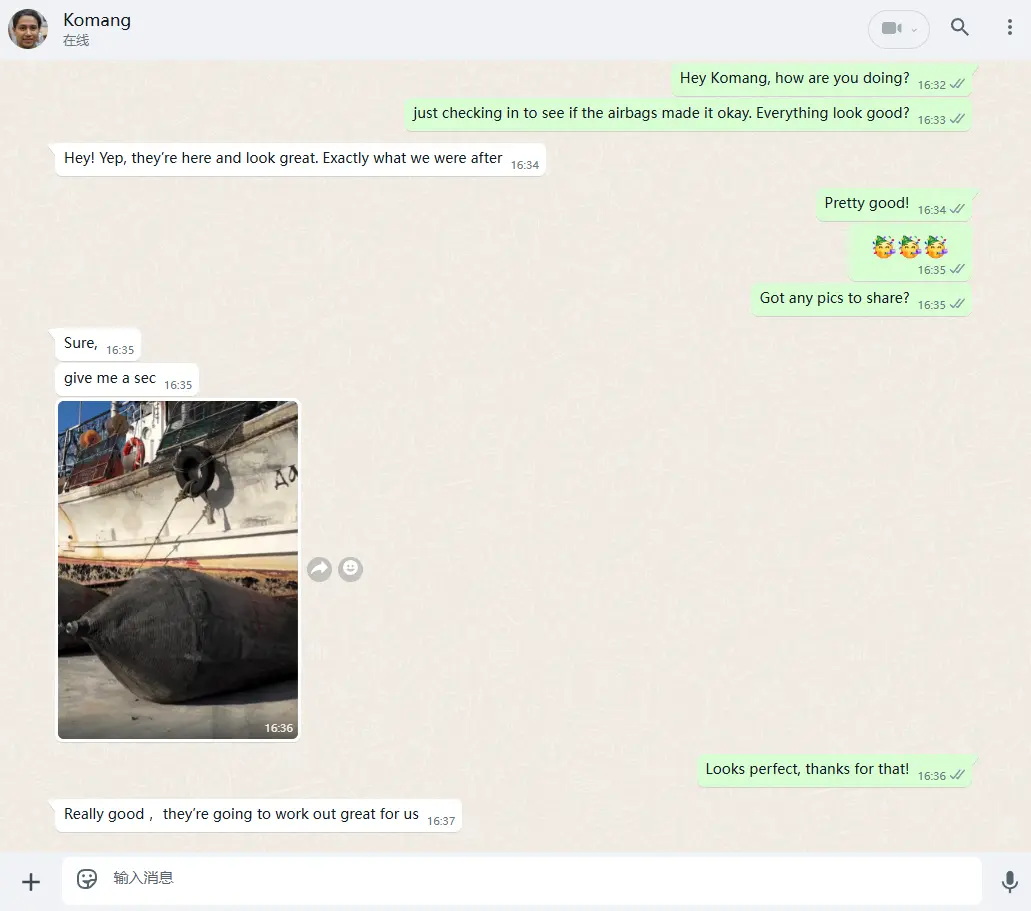

선박용 고무 에어백 애플리케이션

1. 선박 시작 및 업그레이드

중국에서 20년 이상 개발된 선박용 고무 에어백은 선박 진수 및 업그레이드에 가장 신뢰할 수 있고 안정적인 기술임이 입증되었습니다. 톤수 평판에서 10,000톤급 대형 선박에 적합합니다. 한편 외국 조선소, 조선소 및 항만 건설 회사에서도 해양용 고무 에어백을 널리 인정하고 있습니다. 해양 고무 에어백의 선박 진수 및 업그레이드 기술은 미국, 유럽, 동남아시아 및 기타 시장에서도 활발히 추진되고 있습니다.

2. 들어올리기 및 이동

해양 고무 에어백은 항만 건설 작업에서 케이슨을 들어 올리고, 발사하고, 이동하고, 운반하는 데 사용할 수 있습니다.