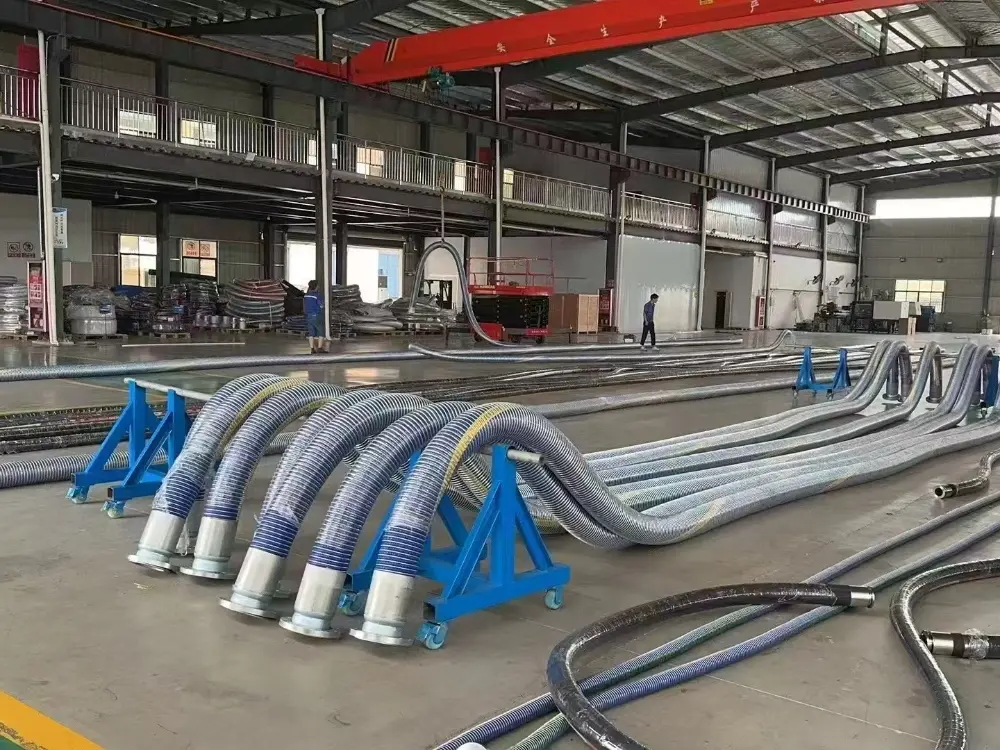

복합 호스 구조

복합 호스는 나선형으로 감싸고 내부 및 외부 와이어 헬기로 지지하는 여러 층의 열가소성 직물 및 필름으로 제조되며, 유체 운송의 구성 요소입니다.

여러 소재 층이 호스의 구조를 견고하게 만들어 압력에 강합니다. 또한 복합 호스를 만드는 데 사용되는 고급 소재는 안전성이 뛰어나 산업 분야에서 복합 호스가 널리 사용되고 있습니다.

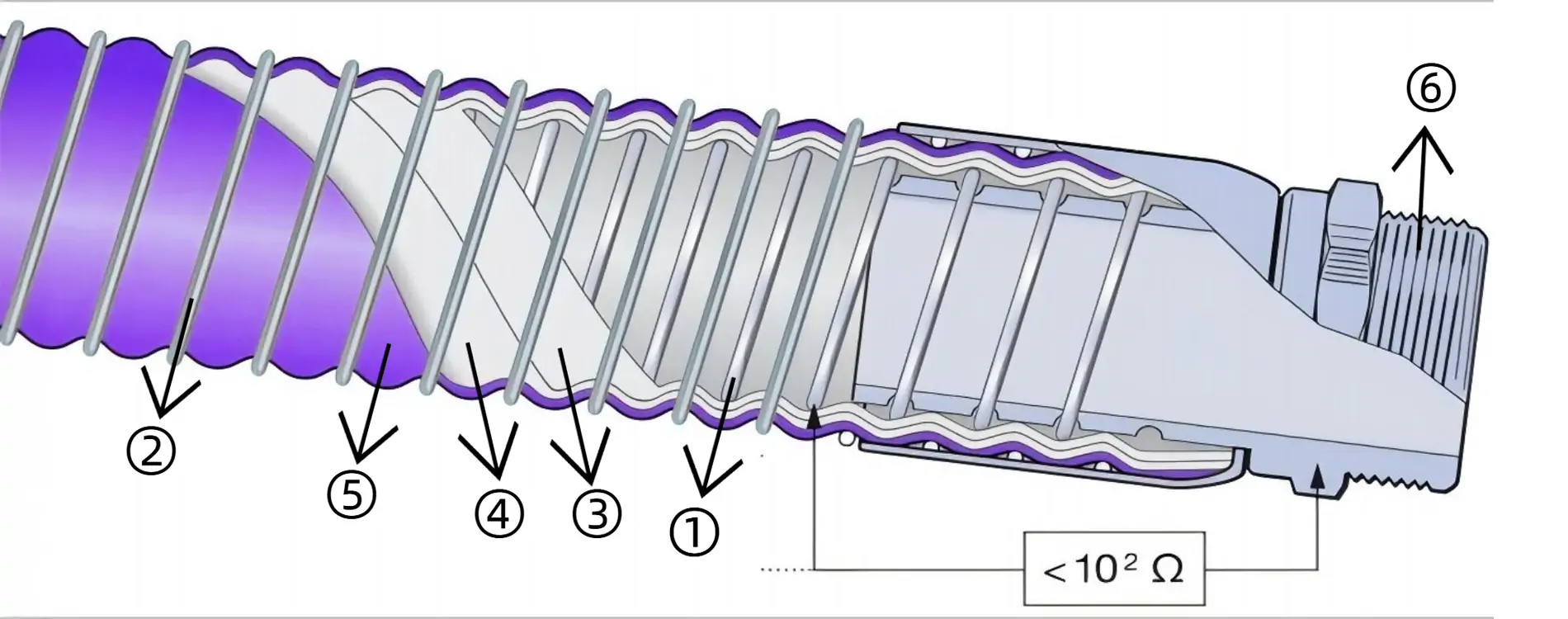

1. 내부 나선형 와이어:

호스 이송 매체의 특성에 따라 스테인리스 스틸 와이어, 아연 도금 스틸 와이어, 알루미늄 합금 와이어(PP, PVDF 피복 스틸 와이어) 등 다양한 재질을 사용할 수 있습니다.

2. 외부 헬리컬 와이어:

아연 도금 강철 와이어, 스테인리스 스틸 와이어, PP 코팅 강철 와이어.

3. 고저항 내부 와이어:

호스의 품질은 선택할 다양한 매체의 특성에 따라 화학적 공격성과 화학적 액체 장벽에 중요한 역할을 합니다.

4. 보강 레이어:

다층 기능성 폴리머 필름과 합성 직물 보강층으로 구성된 후 나선형으로 감싸고 내부 및 외부 와이어 헬기로 지지하는 구조로 되어 있습니다.

5. 안티에이징 아우터 레이어:

외부 레이어는 방수 및 내마모성 PVC 원단으로 제작되어 부식성 화학물질과 탄화수소에 대한 내성이 뛰어납니다. 200°C ~ +200°C(-328°F ~ +392°F)의 온도에서 사용 가능하며 가볍고 안전하며 견고하고 부식 방지, 온도 저항성, 내후성 및 기타 특성을 갖추고 있습니다.

6. 호스 커플링:

다양한 매체에 따라 황동, 알루미늄, 스테인리스 스틸, PP 및 기타 소재의 호스 커플링을 제공할 수 있는 Jerryborg는 보다 전문적이고 신뢰할 수 있는 호스 커플링 시스템을 위한 연결 솔루션을 제공합니다.