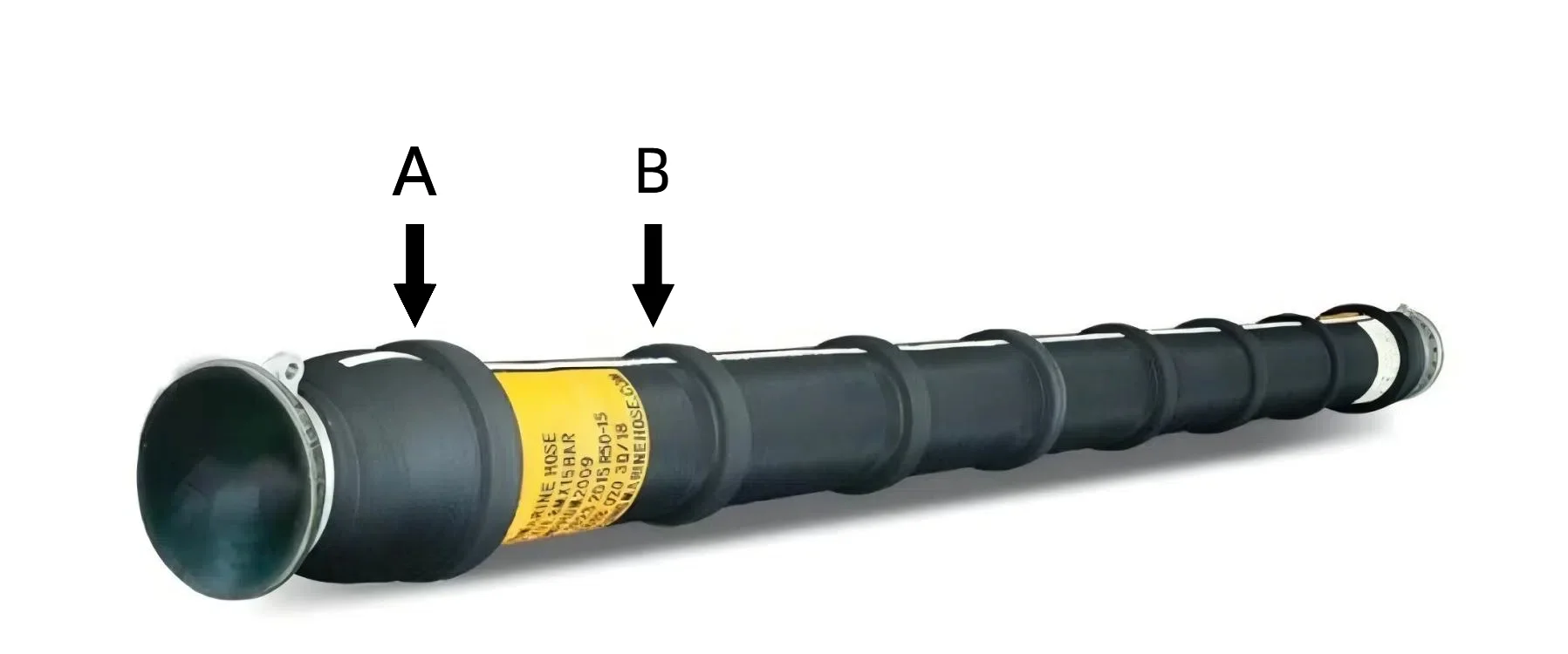

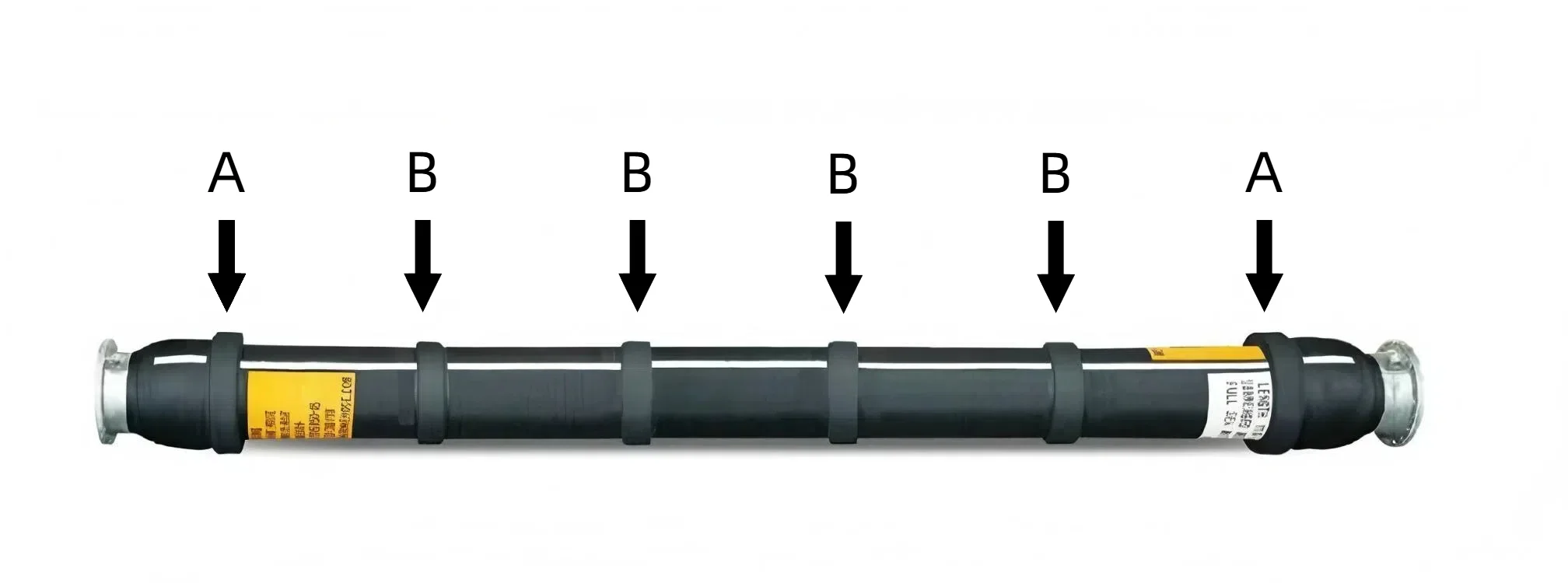

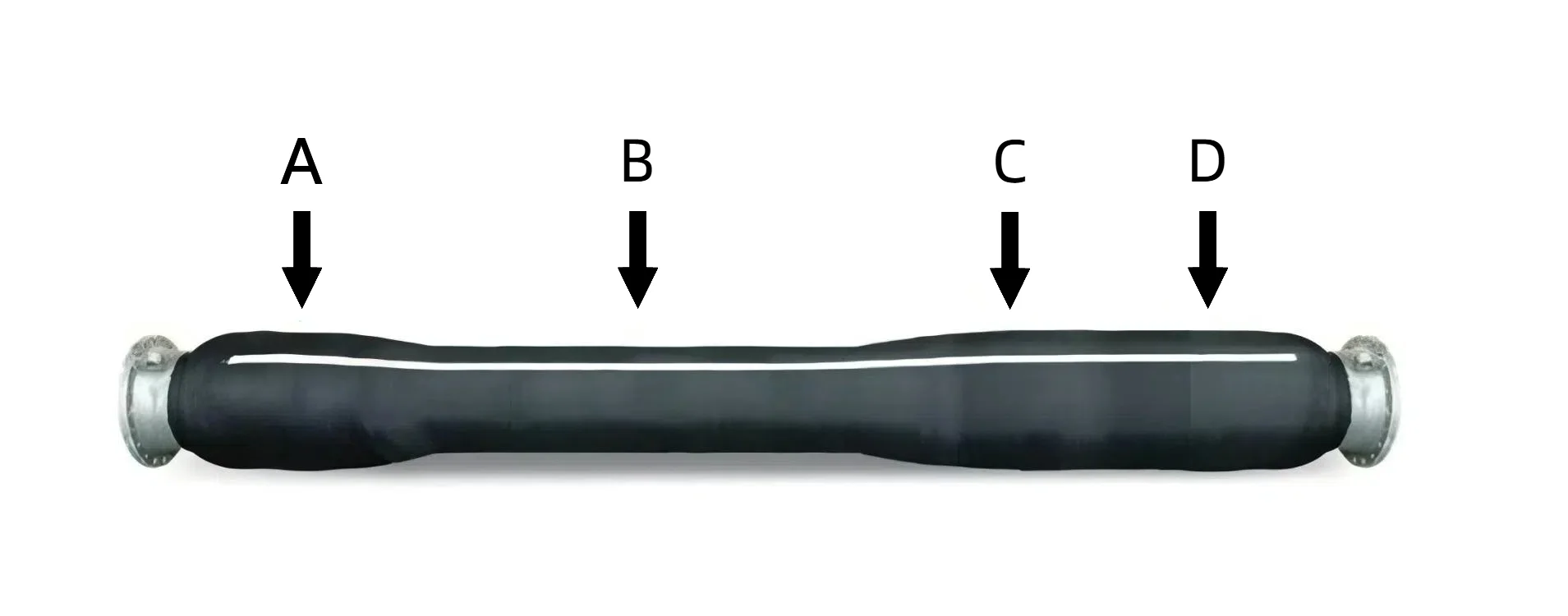

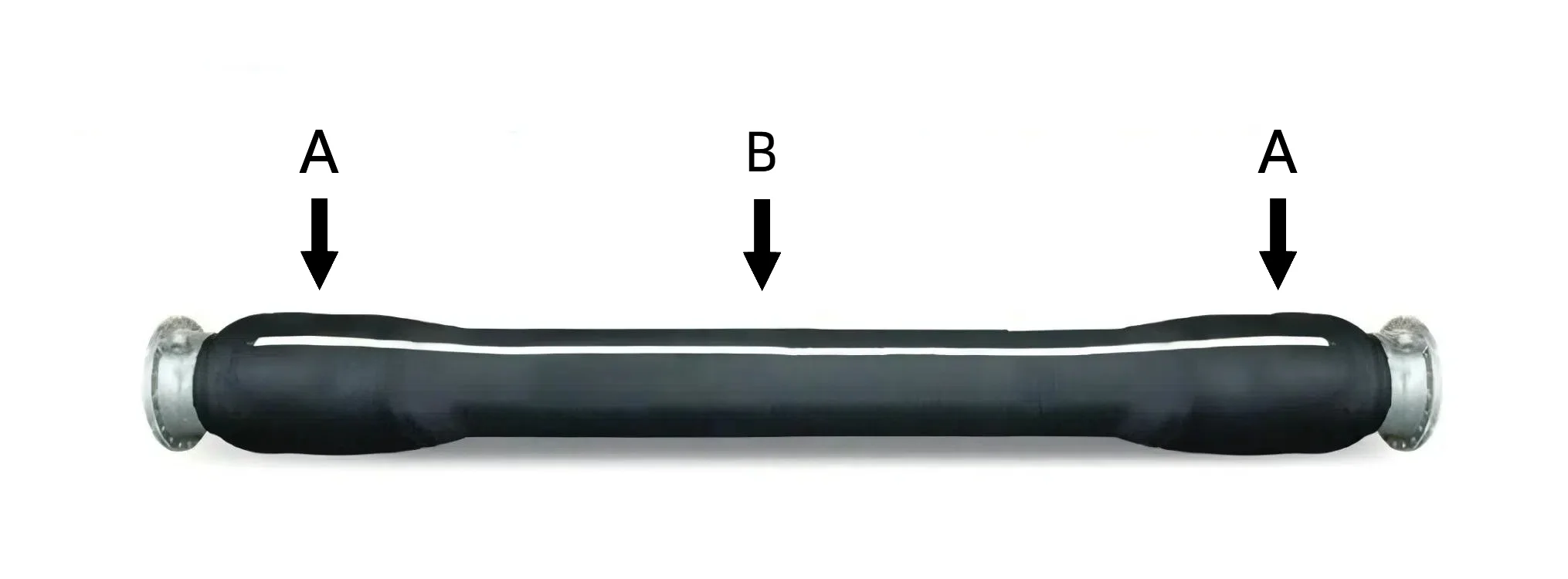

제리보그 잠수함 호스

Jerryborg 잠수함 호스는 열악한 해양 환경에서 사용하도록 설계되었습니다. 라이닝 화합물은 고방향족 탄화수소에 대한 내성이 뛰어나며 압력 서지 및 외부 압축에도 안정적으로 유지됩니다. 호스 구조는 높은 인장 강도, 강력한 층간 접착력, 우수한 파열 압력 성능을 갖추고 있습니다. 내마모성 외층과 압력 하에서 부력 손실이 적은 Jerryborg 호스는 기계식 누출 감지기 및 리프팅 러그 옵션도 함께 제공되어 안전한 작업 하중을 높일 수 있습니다.

Jerryborg 잠수함 호스는 OCIMF 표준을 충족하도록 설계되었으며 ISO 9001:2015 인증 품질 시스템에 따라 제조 및 테스트되어 일관된 성능을 보장합니다.