Em 2024, a Jerryborg forneceu e instalou um sistema de lança permanente na doca regular de submarinos da Marinha chinesa no leste da China. O cliente nos escolheu como fornecedor para fornecer a barreira para evitar derramamentos de óleo durante o reabastecimento e a manutenção dos submarinos nesse local. Após uma visita ao local, nossa equipe descobriu que a água do mar nessa área é relativamente calma e há pouco movimento das marés. Após as discussões finais, recomendamos um boom permanente de poliuretano com flutuadores e correntes de lastro de aço inoxidável.

Implantamos a lança permanente em um formato curvo na área abrigada do porto, perto do píer. O comprimento total da implantação é de cerca de 800 metros. Os pontos de ancoragem são fixados em intervalos para que as ondas não desloquem a barra. Desde sua instalação, a lança permaneceu em uma posição fixa quase o tempo todo, com manutenção mínima. Nossas barreiras também são eficazes na prevenção de resíduos de combustível quando o submarino está ancorado, ajudando nossos clientes a cumprir os padrões de segurança no ambiente marinho.

Esse projeto é um excelente exemplo das barreiras permanentes da Jerryborg Marine sendo usadas em terminais militares e em águas abrigadas. Com base nesse projeto, resumimos os principais recursos técnicos das barras permanentes. Os detalhes completos da documentação técnica podem ser encontrados abaixo.

Especificação técnica da lança de contenção de óleo permanente JRB1000W

1. Estrutura do equipamento e desempenho geral

A lança de contenção permanente de óleo JRB1000W consiste em um corpo de borracha, um corpo flutuante externo, um conector de extremidade (ou conectores de extremidade de alta resistência), pontos de ancoragem, suporte para as mãos, freio de reboque e acessórios.

A barreira permanente de contenção de óleo JRB1000W foi projetada para confinar e redirecionar derramamentos de óleo marinho durante a resposta a incidentes, concentrando efetivamente o óleo derramado para facilitar as operações de recuperação. Essa barreira é capaz de interceptar vários tipos de óleo, incluindo petróleo bruto pesado/médio, óleo combustível e produtos leves de petróleo.

1.1 Confiabilidade

A lança de contenção permanente de óleo JRB1000W e os equipamentos auxiliares são produtos padronizados da nossa empresa. Os materiais e componentes usados nos equipamentos fornecidos são provenientes de fornecedores nacionais de alta qualidade e ecologicamente corretos. Em todos os processos de projeto e fabricação, seguimos rigorosamente os requisitos e as diretrizes práticas do Sistema de Gestão da Qualidade (QMS), do Sistema de Gestão Ambiental (EMS) e as especificações do Sistema de Gestão de Saúde e Segurança Ocupacional (OHSMS). Medidas rigorosas de controle de qualidade são implementadas para garantir a estabilidade do armazenamento a longo prazo e a alta confiabilidade operacional do equipamento em condições exigentes.

A barreira de contenção permanente de óleo JRB1000W é construída por meio de fabricação vulcanizada usando borracha de cloropreno especial e lona impregnada de náilon de alta resistência com várias camadas. Esse projeto oferece vantagens superiores, incluindo alta resistência à tração, resistência a ácidos/álcalis, resistência a óleo, resistência à abrasão, retardamento de chamas, resistência a intempéries, propriedades antienvelhecimento e resistência à corrosão pela água do mar, garantindo desempenho confiável e vida útil prolongada em ambientes marinhos adversos.

A lança de contenção permanente de óleo JRB1000W apresenta um projeto estrutural otimizado com um corpo flutuante externo, permitindo a capacidade de confinamento de óleo em dois lados. Sua alta relação flutuabilidade/peso, desempenho superior de acompanhamento de ondas e excepcional capacidade de retenção de óleo são obtidos por meio de um sistema de flutuabilidade segmentado com várias câmaras. Essa configuração de câmara não contínua garante uma funcionalidade à prova de falhas - mesmo que uma ou mais câmaras estejam comprometidas, as câmaras adjacentes mantêm flutuabilidade suficiente para manter a lança operacional sem comprometer a eficácia geral.

O corpo da lança de óleo é equipado com faixas de identificação para aumentar a visibilidade e proteger contra danos acidentais. A lança utiliza cintas de borracha com mais de 5 mm de espessura para manter a estabilidade vertical e a alta resistência à tração, garantindo a distribuição uniforme da tensão e a integridade estrutural robusta.

Os conectores deslizantes (dobradiça ou outros conectores de alta resistência) são fabricados em liga de alumínio resistente à corrosão para ambientes marinhos, enquanto os fixadores de aço inoxidável e os revestimentos de proteção nos demais componentes metálicos garantem confiabilidade e durabilidade a longo prazo.

Todo o sistema foi projetado para uma operação segura e intuitiva, facilidade de armazenamento e transporte e baixa manutenção.

1.2 Universalidade

O equipamento deve ser técnica e operacionalmente compatível com as embarcações existentes e com outros sistemas de resposta a derramamentos de óleo, incluindo equipamentos de contenção, recuperação, armazenamento e transporte, para garantir uma interoperabilidade perfeita e alcançar um desempenho colaborativo ideal.

1.3 Operabilidade

O sistema completo oferece uma operação fácil de usar, confiável, prática e durável com baixos custos operacionais. A lança pode ser configurada rapidamente por meio de instalação rebocada por navio com suporte manual, atingindo uma velocidade de configuração de 200 metros em 20 minutos.

As barras adjacentes são rapidamente interconectadas por meio de conectores deslizantes (conectores de dobradiça ou outros conectores de alta resistência) para montar comprimentos personalizados, garantindo uma integração perfeita com barras que apresentam conectores compatíveis. A superfície lisa e não porosa da barra permite uma limpeza sem esforço e minimiza a retenção de óleo residual.

1.4 Compatibilidade

O equipamento foi projetado de acordo com padrões industriais internacionais e apresenta interfaces de conectividade altamente compatíveis, permitindo a conexão rápida e conveniente com barreiras de óleo da maioria dos fabricantes nacionais e internacionais de recuperação de derramamento de óleo. Sua interoperabilidade universal garante uma integração perfeita entre diversos sistemas.

1.5 Capacidade de manutenção

A lança de contenção permanente de óleo JRB1000W utiliza componentes padronizados, garantindo a fácil substituição de peças sobressalentes e manutenção econômica. O sistema requer manutenção de rotina para garantir a prontidão operacional contínua e a capacidade de implantação de emergência.

Nossa empresa oferece uma estrutura confiável de serviços pós-venda, incluindo estoques de peças de reposição de fabricação própria, assistência técnica remota e suporte de campo no local para garantir a funcionalidade ininterrupta dos equipamentos de resposta a emergências.

1.6 Durabilidade

Os materiais usados na parte externa e interna do equipamento fornecido são resistentes a óleo, corrosão, desgaste, sal, clima, envelhecimento e água do mar.

1.7 Padrões e especificações adotados pelo equipamento

Todo o conjunto de equipamentos deve estar em conformidade com as versões mais recentes ou revisadas das normas ISO relevantes, das normas nacionais do meu país ou de outras normas nacionais estrangeiras reconhecidas.

- Parâmetros nominais: ISO

- Medição e dimensões: SI

- Pintura: SIS

- Barreiras de óleo: GB/T34621-2017

- Pictogramas e sinais de embalagem, armazenamento e transporte: GB/T191-1990

2. Lança de contenção permanente de óleo JRB1000W

2.1 Introdução

A barreira permanente de contenção de óleo JRB1000W foi projetada para conter, redirecionar e concentrar derramamentos de óleo marinho durante incidentes, permitindo uma recuperação eficiente por meio de métodos físicos. O óleo residual que é difícil de recuperar pode ser tratado usando técnicas de remediação química, física ou biológica. Essa barreira é capaz de interceptar óleos brutos pesados e médios, óleos combustíveis, produtos petrolíferos leves e hidrocarbonetos semelhantes.

Fabricada com tecido revestido de borracha resistente a óleo de alta resistência à tração, a lança JRB1000W oferece capacidade de carga robusta em condições operacionais de alta tensão.

Ele é adequado para implantação em portos, portos, plataformas de perfuração offshore e operações de resposta a emergências marítimas.

O equipamento é projetado, fabricado e inspecionado em total conformidade com a Norma Nacional da China GB/T 34621-2017 "Oil Booms", emitida pelo Ministério dos Transportes.

2.2 Estrutura

A barreira de petróleo é classificada como uma barreira de flutuação sólida. Sua seção superior incorpora flutuadores, enquanto a seção inferior é equipada com blocos de lastro, garantindo que a lança mantenha a estabilidade vertical em ambientes aquáticos.

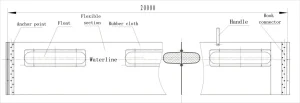

A lança de contenção permanente de óleo JRB1000W consiste em um corpo de borracha, corpo flutuante externo, conector de gancho (ou conectores de alta resistência), pontos de ancoragem, alça, freio de reboque e acessórios. Conforme ilustrado abaixo:

2.2.1 Corpo de borracha: Formado por meio de processamento de vulcanização usando tecido revestido de borracha de cloropreno de alta resistência, resistente a óleo, a intempéries e à corrosão.

2.2.2 Flutuadores: São compostos por invólucros de plástico de polietileno (PE) com interiores preenchidos com espuma, montados com segurança no corpo de borracha por meio de parafusos de aço inoxidável.

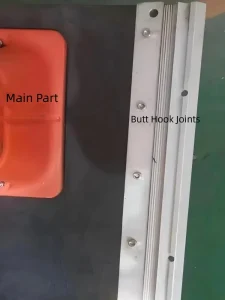

2.2.3 Conector de gancho: Conector de gancho em conformidade com o padrão GB/T34621-2017 para barreiras de petróleo, fabricado em liga de alumínio resistente à corrosão por água do mar e fixado ao corpo de borracha com fixadores de aço inoxidável. (Projetos alternativos de conectores de alta resistência estão disponíveis como opção).

2.2.4 Ponto de ancoragem: Abaixo do conector deslizante, há manilhas integradas para prender as linhas de ancoragem.

2.2.5 Alça: As alças de elevação, fabricadas com tecido revestido de borracha resistente a óleo, são fixadas ao corpo da lança por meio de parafusos de compressão de aço inoxidável, permitindo o manuseio manual durante a implantação e a recuperação.

2.3 Desempenho da barreira permanente de contenção de óleo JRB1000W

2.3.1 A qualidade da aparência da borracha da barreira de óleo excede os requisitos da norma HG/T3046. Todos os componentes metálicos estão firmemente colados, limpos e sem rebarbas;

2.3.2 O invólucro da lança é construído com lona impregnada de borracha e borracha resistente a óleo, com a lona fornecendo uma resistência à tração de 300 N/mm e resistência ao rasgo de 1.030 N. Cada seção apresenta uma construção longitudinal sem emendas, sem conectores, bolhas, dobras ou rachaduras. A camada externa de borracha é resistente a óleo, ácidos, álcalis, corrosão por água do mar e envelhecimento por raios UV e opera de forma confiável em temperaturas que variam de -40℃ a +70℃. O tecido revestido de borracha apresenta uma força de ligação entre camadas de 11,5 N/mm e uma força de adesão entre superfície e substrato de 12 N/mm. A barreira de contenção de óleo apresenta um design bilateralmente simétrico, permitindo que qualquer uma das faces seja implantada em direção a derramamentos de óleo para operações de contenção eficazes.

2.3.3 Componentes estruturais de metal: O conector deslizante é fabricado em liga de alumínio resistente à corrosão por água do mar, enquanto os fixadores (por exemplo, parafusos) são feitos de aço inoxidável. Os materiais não metálicos empregam compostos resistentes à água do mar, ao clima e ao óleo. O produto está livre de defeitos que prejudiquem a integridade funcional.

2.3.4 As unidades de flutuação são construídas com plástico de polietileno (PE) de alta resistência, que é resistente a óleo, ácidos, álcalis, corrosão pela água do mar e degradação por raios UV. Cada flutuador contém núcleos de espuma de célula fechada, garantindo que não haja defeitos que comprometam o desempenho.

2.3.5 O conector utiliza conectores deslizantes para montagem no local, proporcionando total intercambialidade entre as seções da lança. Durante a implantação estática, a lança mantém a borda livre e o calado estáveis para garantir a confiabilidade operacional.

2.3.6 Todos os acessórios da lança apresentam um acabamento superficial impecável - limpo, sem rebarbas e sem irregularidades. Todo o sistema está em conformidade com a norma GB/T34621-2017 "Oil Containment Booms" do Ministério dos Transportes

2.3.7 A vida útil normal não é inferior a 5 anos, e a vida útil normal de armazenamento não é inferior a 8 anos.

2.4 Conector de extremidade

Vários métodos de conexão estão disponíveis de acordo com os requisitos operacionais, incluindo conectores deslizantes, conectores de dobradiça, conexões de placa de grampo e sistemas híbridos de grampo de corda que combinam cabos de aço inoxidável com ilhós reforçados. Os conectores são totalmente intercambiáveis e têm os seguintes recursos::

2.4.1 A altura do conector é a altura total da lança de óleo;

2.4.2 As seções de lança interconectadas exibem distribuição e transmissão de carga de tração uniforme durante as operações, evitando a sobrecarga localizada;

2.4.3 O conector consegue uma vedação à prova de vazamentos após a conexão, eliminando os riscos de vazamento de óleo nas interfaces;

2.4.4 As conexões permanecem operacionalmente viáveis em condições de contaminação por óleo, acúmulo de detritos ou formação de gelo;

2.4.5 A montagem/desmontagem rápida pode ser realizada em ambientes submersos e em terra, sem equipamento especializado;

2.4.6 Não há impacto sobre o desempenho da barreira de petróleo, incluindo borda livre, desempenho de elevação, condução de ondas, estabilidade, etc.);

2.4.7 O design garante funcionalidade independente da temperatura com construção leve e retenção estável da flutuabilidade;

2.4.8 Não são necessárias ferramentas especializadas de montagem/desmontagem para operações de campo;

2.4.9 Sem partes salientes que possam causar emaranhamento, ferimentos ou perfurações; sem risco de ferimentos para o pessoal。

2.4.10 A resistência à tração do conector excede a resistência à tração da membrana;

2.4.11 A seleção dos conectores levou em consideração fatores como peso, resistência mecânica, estabilidade química, flexibilidade e condições ambientais das águas de operação。

2.4.12 O freio de reboque com lança de óleo pode ser selecionado de acordo com as necessidades do usuário.

2.5 Principais especificações técnicas

| Nome/Modelo | Lança de contenção permanente de óleo JRB1000W |

| Altura total | 1000 mm |

| Borda livre | 400 mm |

| Rascunho | 600 mm |

| Comprimento da seção da lança | 20m |

| Conector de extremidade | Conector deslizante |

| Saia | Tecido de borracha de cloropreno (neoprene) com resistência a óleo, resistência a intempéries, resistência à abrasão, resistência à corrosão e resistência à água do mar |

| Cor | Preto |

| Flutuação | Posição: externa

Tipo: feito de concha de plástico de polietileno com estofamento de espuma no interior. |

| Quantidade de flutuação | 14 peças (28 semi-flutuantes) |

| Peso | 15.25kg/m(305Kg/section) |

| Relação entre a flutuabilidade bruta e o peso da lança | 4.49:1 |

| Resistência geral à tração | 600KN |

| Resistência à tração da barreira de óleo | 200KN |

| Temperatura operacional | -30~60℃ |

| Temperatura de armazenamento adequada | -40~60℃ |

| Resistência máxima à altura da onda | 2.0m |

| Resistência máxima à velocidade do vento | 25 m/s ou mais |

| Resistência máxima à velocidade da vazão | 3Knot |

| Velocidade máxima de reboque em linha reta | 10Nós |

| Ambiente de uso | Água protegida |

2.6 Embalagem, aparência e marcações

2.6.1 Embalagem

As barreiras de óleo devem ser embaladas em sacos de embalagem flexíveis ou em embalagens a granel, com cada lote contendo um certificado de conformidade, especificações técnicas e lista de embalagem. A superfície externa da embalagem deve estar claramente marcada com o nome do produto, o número do modelo, o nome do fabricante e as informações do destinatário.

2.6.2 Marcações

- As etiquetas de identificação devem ser marcadas em posições proeminentes de ambas as extremidades de cada seção da lança;

- O conteúdo da etiqueta deve incluir o modelo do produto, o nome do fabricante (ou o logotipo da marca registrada) e a data de produção;

- A linha de base do texto nos rótulos deve se alinhar precisamente com a linha de rascunho da barra;

- Uma faixa amarela deve ser pintada com spray longitudinalmente ao longo do corpo da lança;

- O logotipo é claro, firme e vívido; não é fácil de ser lavado pela água.

3. Escopo do fornecimento

| NÃO. | Especificações | Nome | Quantidade |

| 1 | JRB1000W-00 | barreira permanente de contenção de óleo | 55m |

| 2 | JRB1000W-01 | Manilha | 4 unidades |

| 3 | M10 | barra de borboleta | 8pcs |

4. Lista de peças sobressalentes e ferramentas

| NÃO. | Especificações | Nome | Quantidade |

| 1 | M10 | manilha | 2 unidades |

| 2 | lençol de borracha para reparos | 0.5m2 | |

| 3 | cola para reparos (0,85L/garrafa) | 1 unidade | |

| 4 | tesouras | 1 unidade | |

| 5 | caixa de ferramentas | 1 unidade |

5. Requisitos ambientais

Altura máxima adequada da onda de trabalho: 2,0 m

Taxa de fluxo de trabalho máxima adequada: 3,0Kn

Velocidade máxima de vento adequada para o trabalho: 25 m/s

Temperatura de trabalho adequada: -40~70℃

Umidade de trabalho adequada: 0~100RH

Adaptação às condições do mar: aplicável a portos marítimos abertos e águas de cais