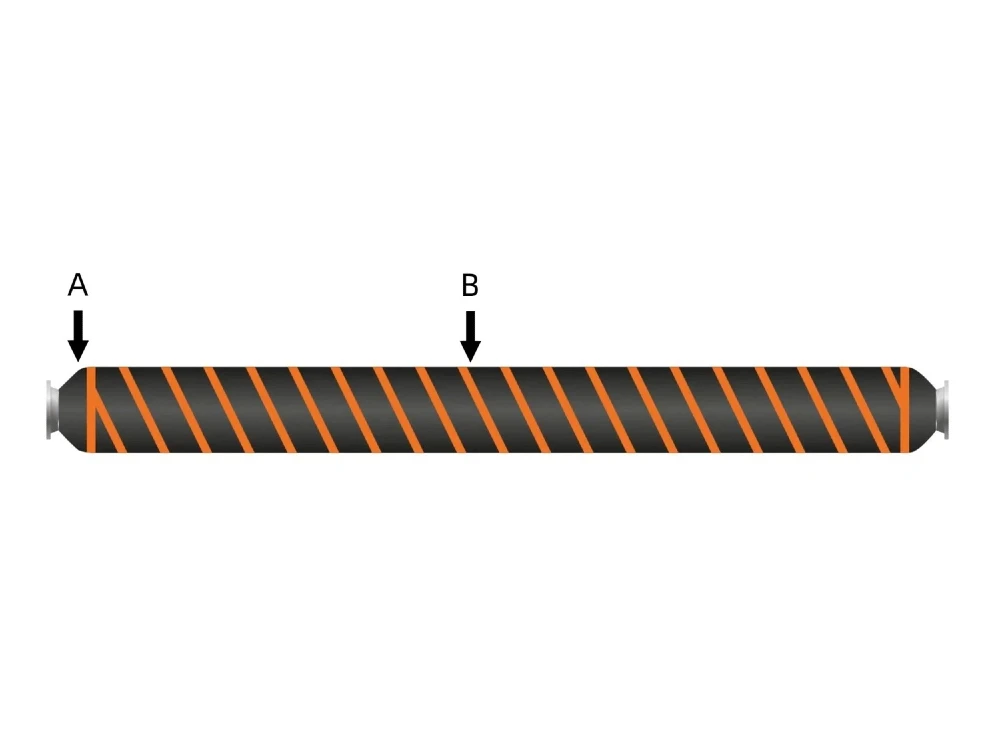

Mangueira flutuante completa da linha principal

As mangueiras flutuantes marítimas são usadas principalmente em sistemas de amarração offshore. Elas são responsáveis pela transferência, manuseio e transporte de petróleo bruto ou produtos líquidos de petróleo entre navios.

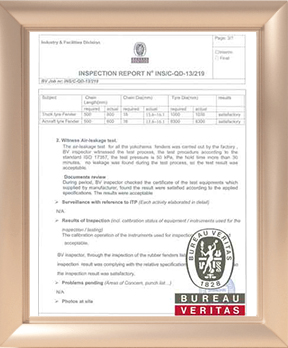

Teste de mangueiras flutuantes

A Jerryborg Marine pode fabricar e testar mangueiras flutuantes de acordo com o padrão GMPHOM 2009 (OCIMF) ou com os padrões especificados pelo cliente.

Obter uma cotação