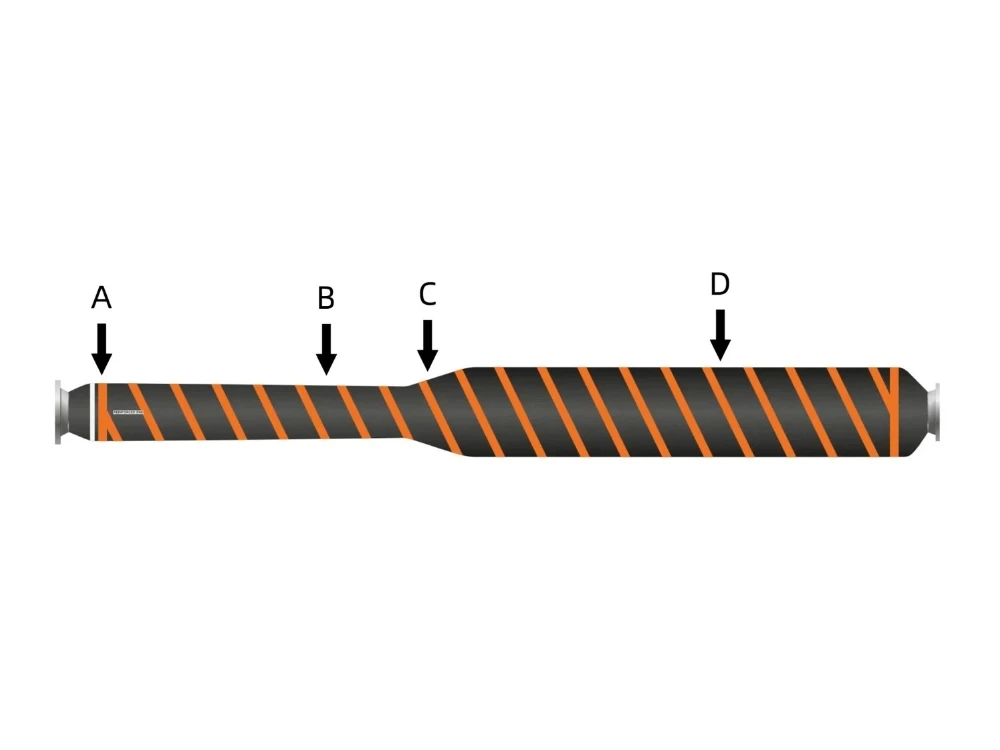

Meia mangueira flutuante reforçada em uma extremidade

A mangueira semi-flutuante é reforçada em uma extremidade. Ela se conecta a boias SPM (Single Point Mooring) ou CALM (Catenary Anchor Leg Mooring). Ela permite a transferência de petróleo entre um FPSO (Floating Production, Storage and Offloading) e um navio-tanque.

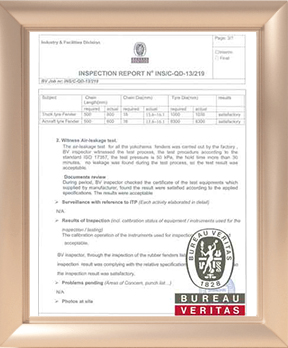

Teste de mangueira semi-flutuante reforçada com uma extremidade

A Jerryborg Marine pode fabricar e testar mangueiras flutuantes de acordo com o padrão GMPHOM 2009 (OCIMF) ou com os padrões especificados pelo cliente.

Obter uma cotação