Marine Breakaway Couplings

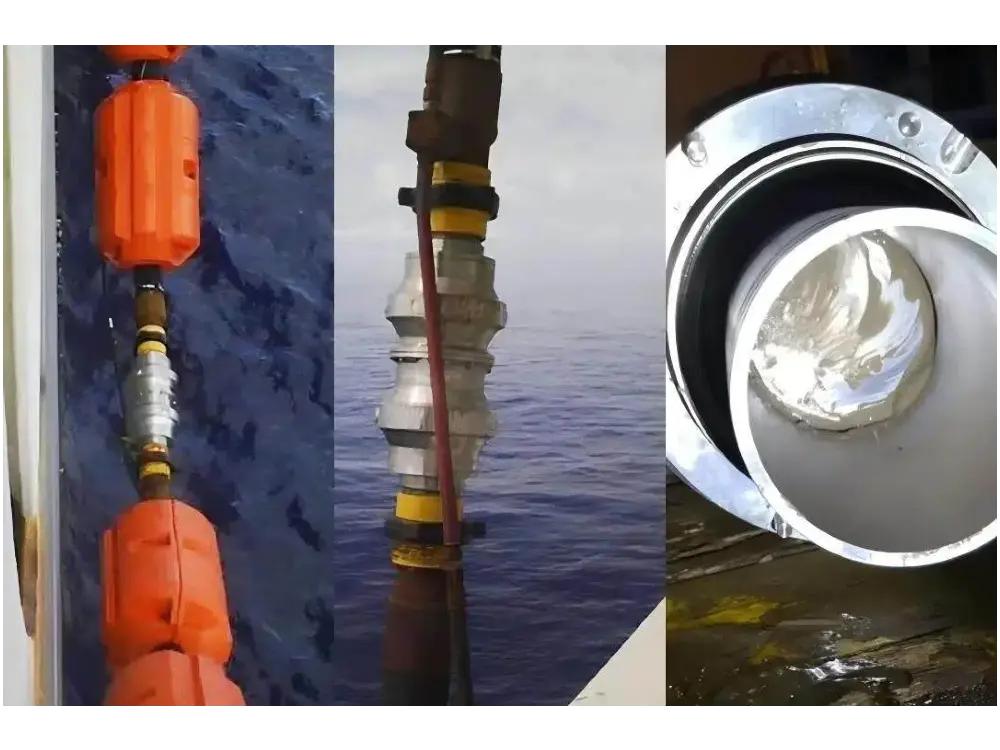

Fluid transport operations in nearshore environments are often characterized by complex conditions. Tankers may unexpectedly detach from moorings due to external factors, and pressure changes may occur within the system. These anomalies can easily lead to media leakage. Simultaneously, transport hoses and related connecting components may be damaged.

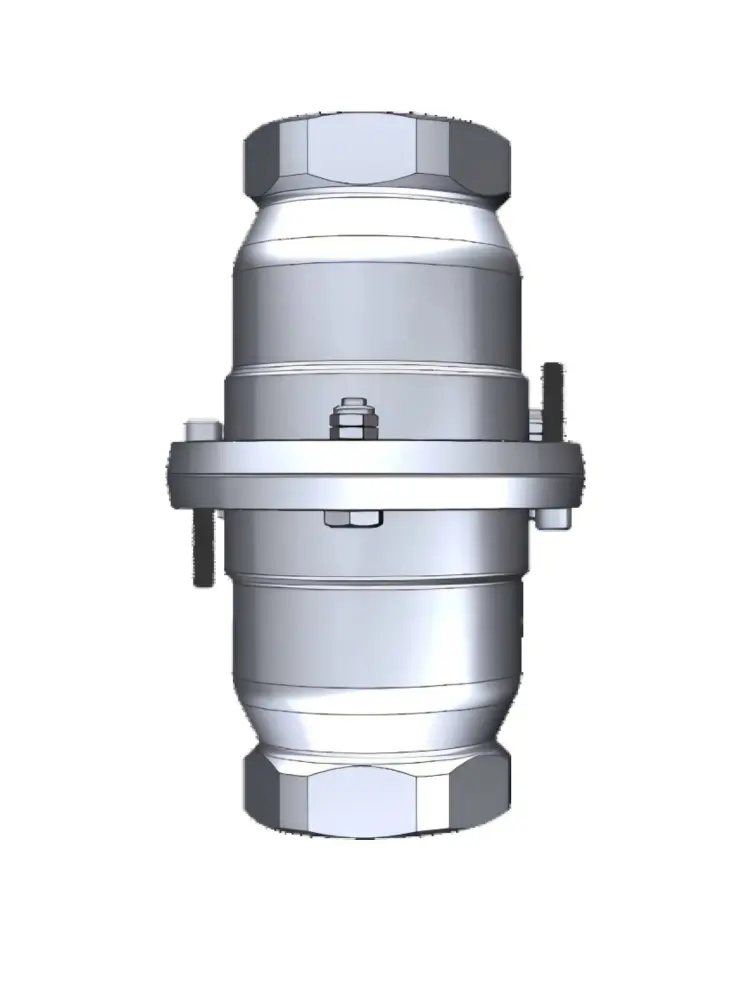

Jerryborg Marine’s breakaway couplings protect ship-to-shore fluid transport systems. These couplings can disengage under pre-defined conditions when subjected to excessive tensile force or a sudden increase in internal pressure. This method improves operational safety by preventing or reducing damage to hoses and couplings under overload conditions.

In practical use, these risks are often related to environmental factors. Excessive wind, waves, or currents can lead to unstable mooring conditions or even mooring failure. In such situations, the external forces on the hoses will increase significantly, posing a risk of rupture. Furthermore, improper valve operation or media flow obstruction can cause a rapid increase in internal pipeline pressure. Sustained or sudden high pressure can also damage the hose itself and its connectors.

To ensure that the selected breakaway coupling is suitable for the actual working conditions and meets the system’s long-term operational requirements, Jerryborg Marine will communicate thoroughly with the customer.

During the solution confirmation process, the following will be the focus: the specific location of the project or terminal, on-site environmental conditions, pipeline dimensions, medium flow requirements, and system design pressure.

All marine breakaway couplings provided by Jerryborg Marine are designed and manufactured under a standardized quality management system. Related products comply with ISO 9001 standards and refer to the latest OCIMF technical guidelines. They can be applied to various offshore and port fluid transportation scenarios.

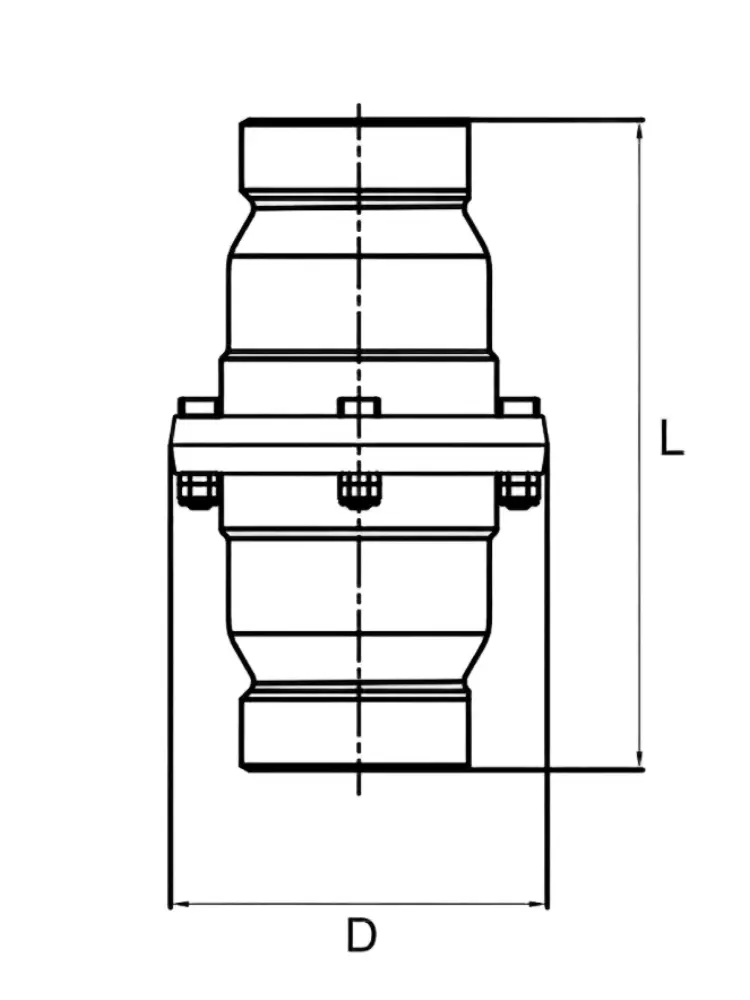

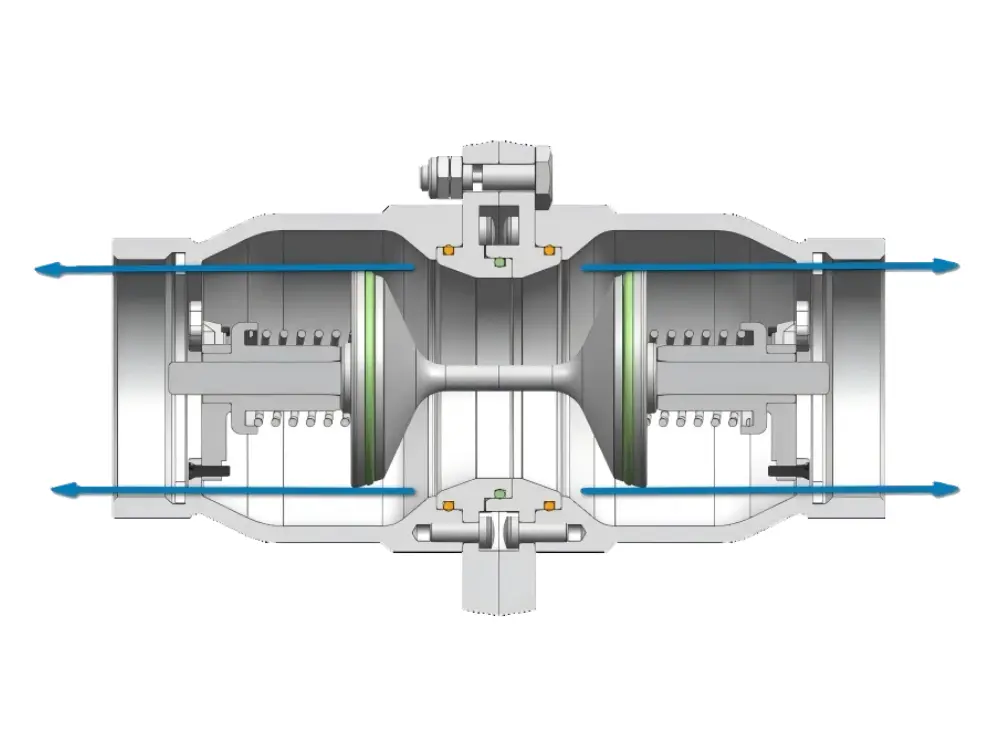

Coupling before emergency disconnect

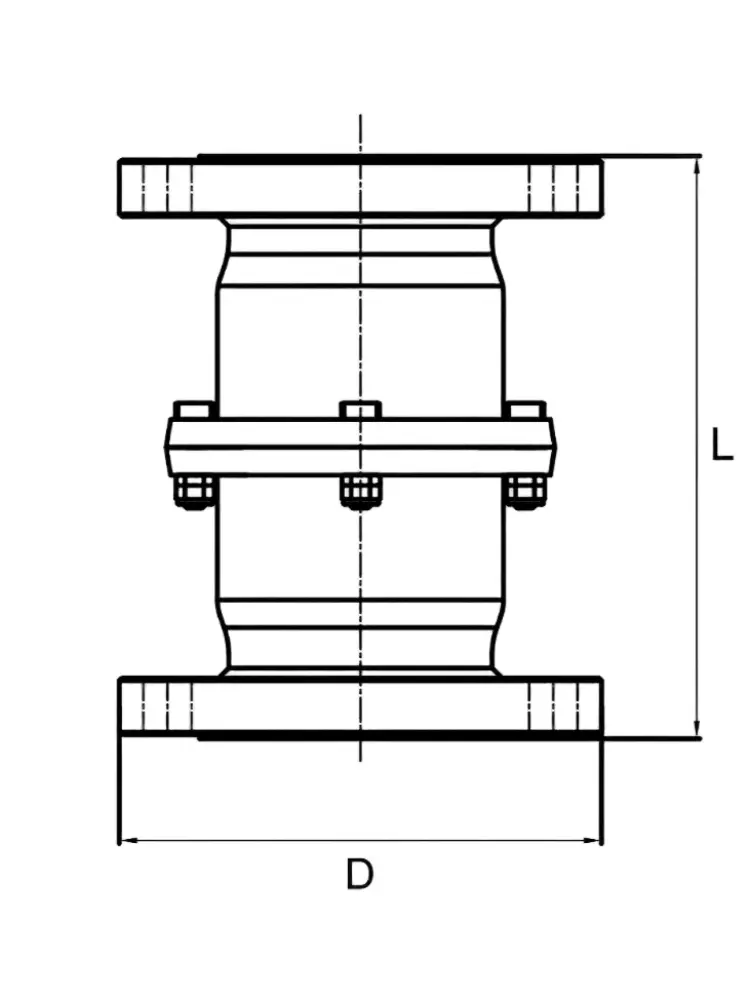

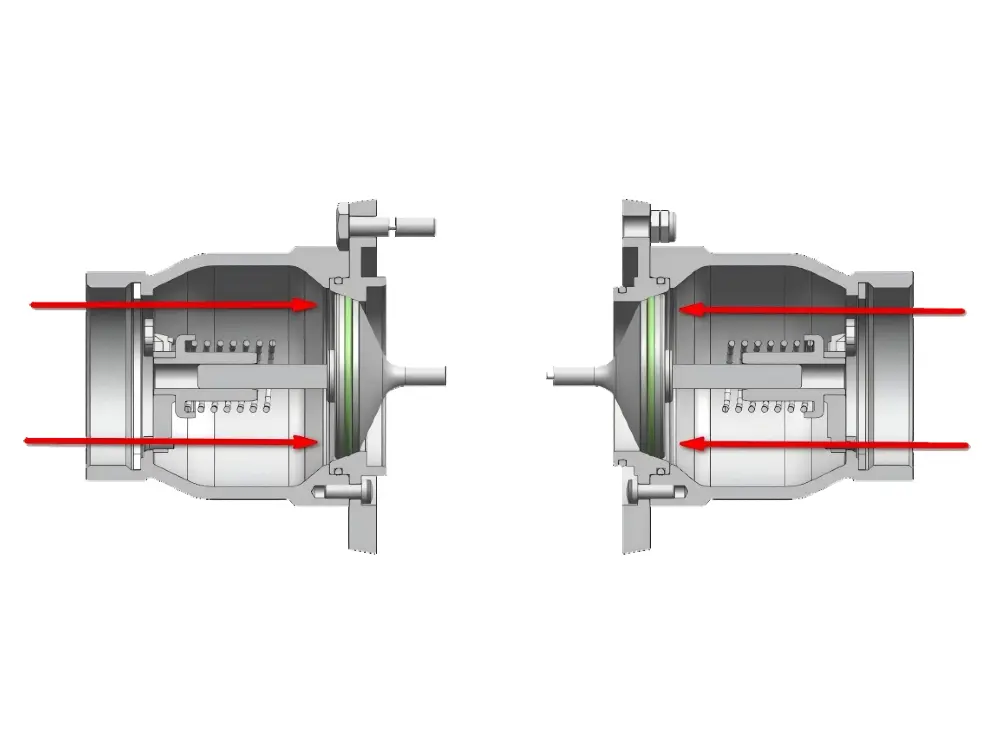

Coupling after emergency disconnect