2. Unidad de alimentación

El Power Pack integra un motor diésel, una bomba de transferencia de aceite y una estación hidráulica, todo ello montado en un bastidor de carro de cuatro ruedas. El motor diésel sirve como fuente de energía primaria.

La bomba de trasiego de aceite es una bomba de impulsor flexible con gran capacidad de autocebado, capaz de manejar fluidos que contienen pequeñas partículas sólidas. Esta bomba se acopla directamente al motor diésel mediante un acoplamiento elástico.

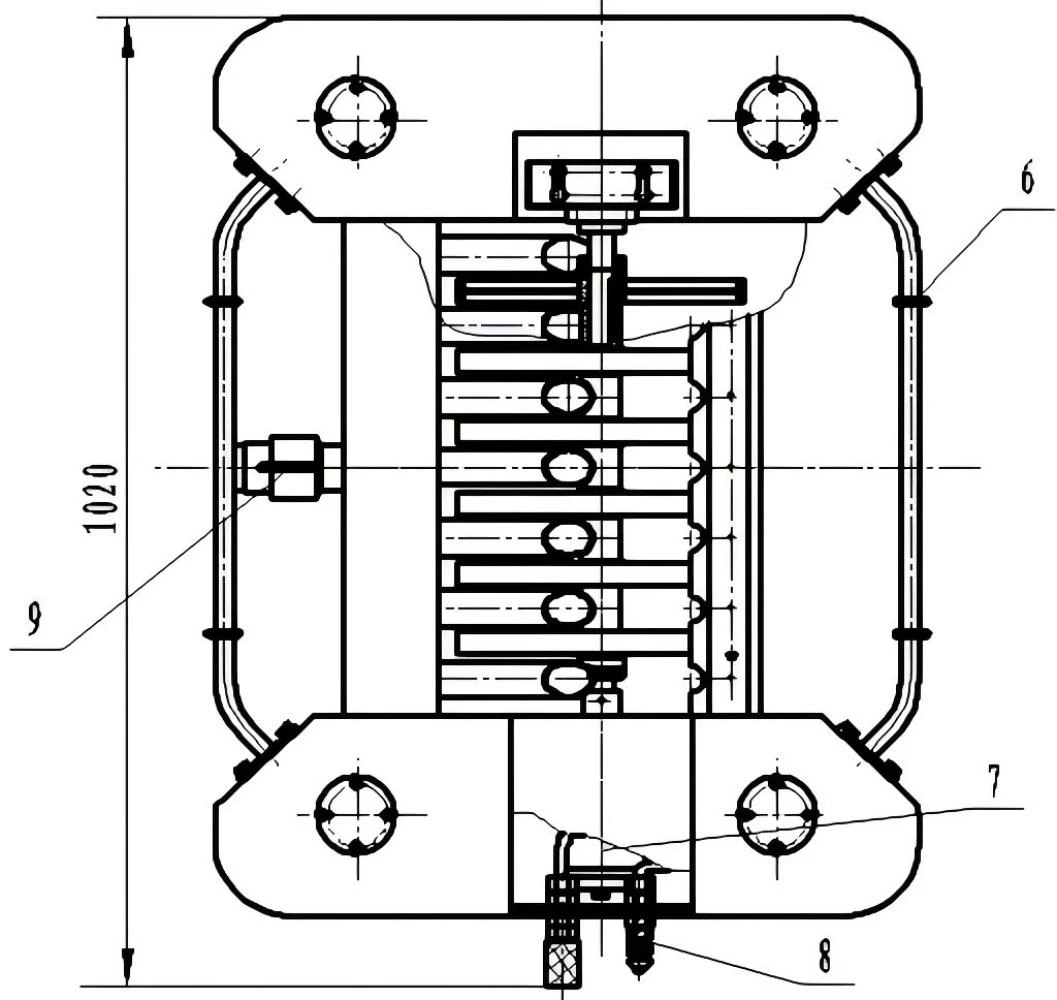

La estación hidráulica consta de tres componentes principales: una bomba hidráulica, un depósito y un bloque distribuidor, interconectados por conductos hidráulicos. La bomba hidráulica es accionada mecánicamente por el motor diésel.

El depósito y el bloque del colector están equipados con un filtro de aire, un manómetro, un indicador de temperatura y de nivel, una válvula de cierre de alta presión (para el arranque del motor), una válvula de alivio, una válvula de control de caudal y un filtro fino de la línea de retorno. El bloque colector incluye una entrada de aceite hidráulico para alimentar el motor hidráulico del cabezal de recuperación de aceite. Al mismo tiempo, el filtro de la línea de retorno presenta una salida de aceite hidráulico conectada al puerto de retorno del motor. Además, el bloque distribuidor contiene una válvula de cierre de alta presión (para el arranque del motor), una válvula de alivio, una válvula de control de caudal y una entrada de aceite hidráulico específica para alimentar el puerto de admisión del motor.