Stalen meerboeien Beschrijving

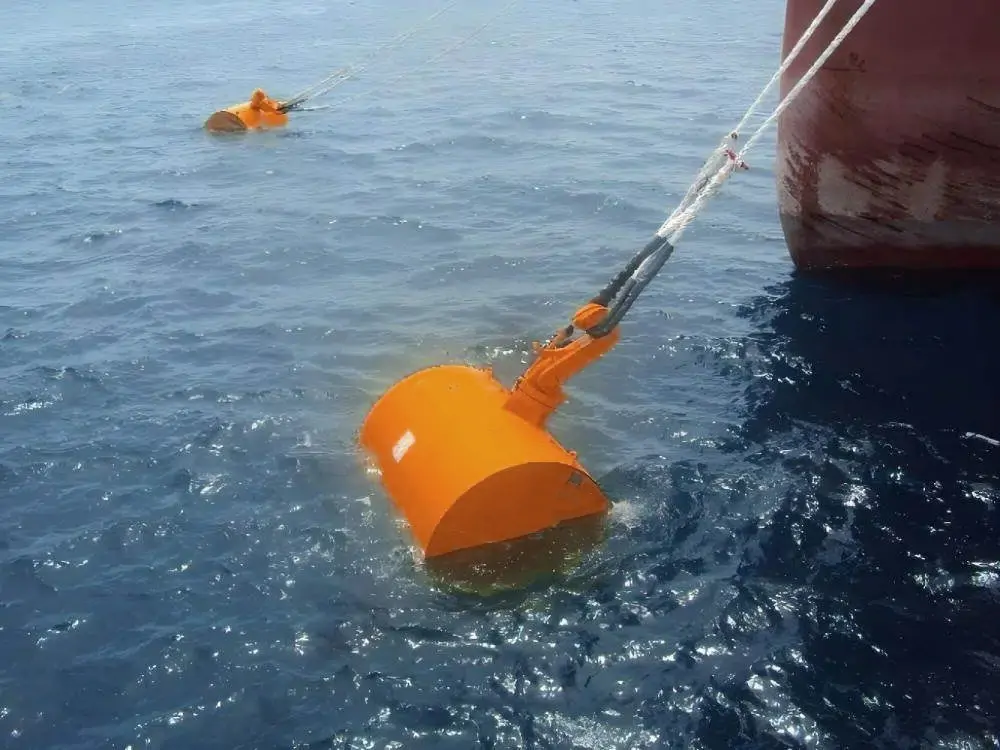

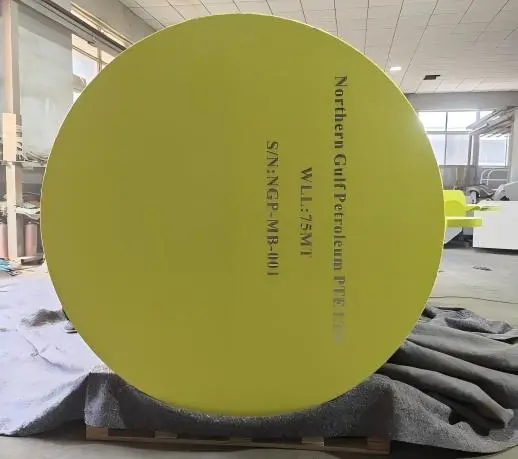

Jerryborg biedt een grote verscheidenheid aan meerboeien. Deze boeien kunnen voor extra aanlegruimte zorgen door een vaartuig of vaartuig midden in het water of bij een aanlegplaats te verankeren. Ze kunnen een vaartuig veilig verankeren en voorkomen dat het gaat drijven. Ze kunnen ook tijdelijke vaartuigen een ligplaats bieden in een aangrenzende haven wanneer ze niet in aanmerking komen voor een ligplaats in een jachthaven. Jerryborg meerboeien voldoen aan alle industriële voorschriften en de eisen van de kustwacht.