Jerryborg Yokohama-type Pneumatic Fenders

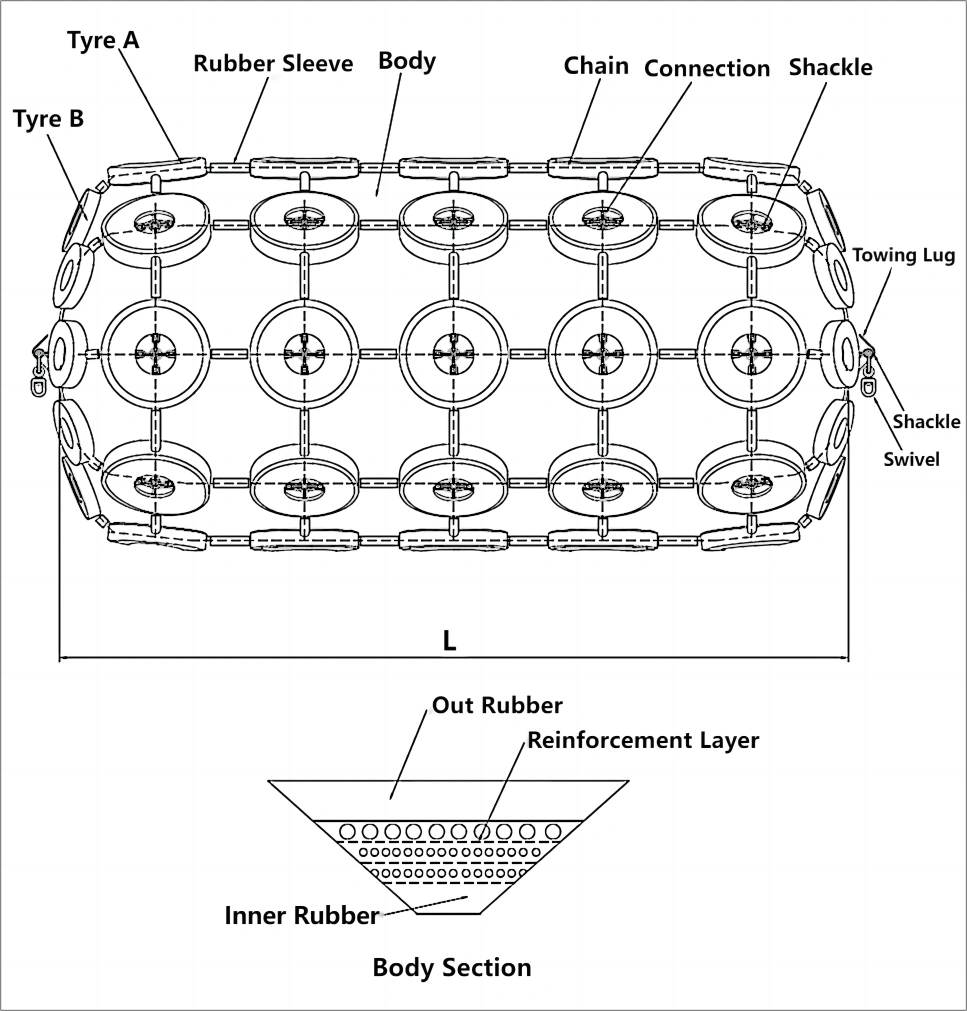

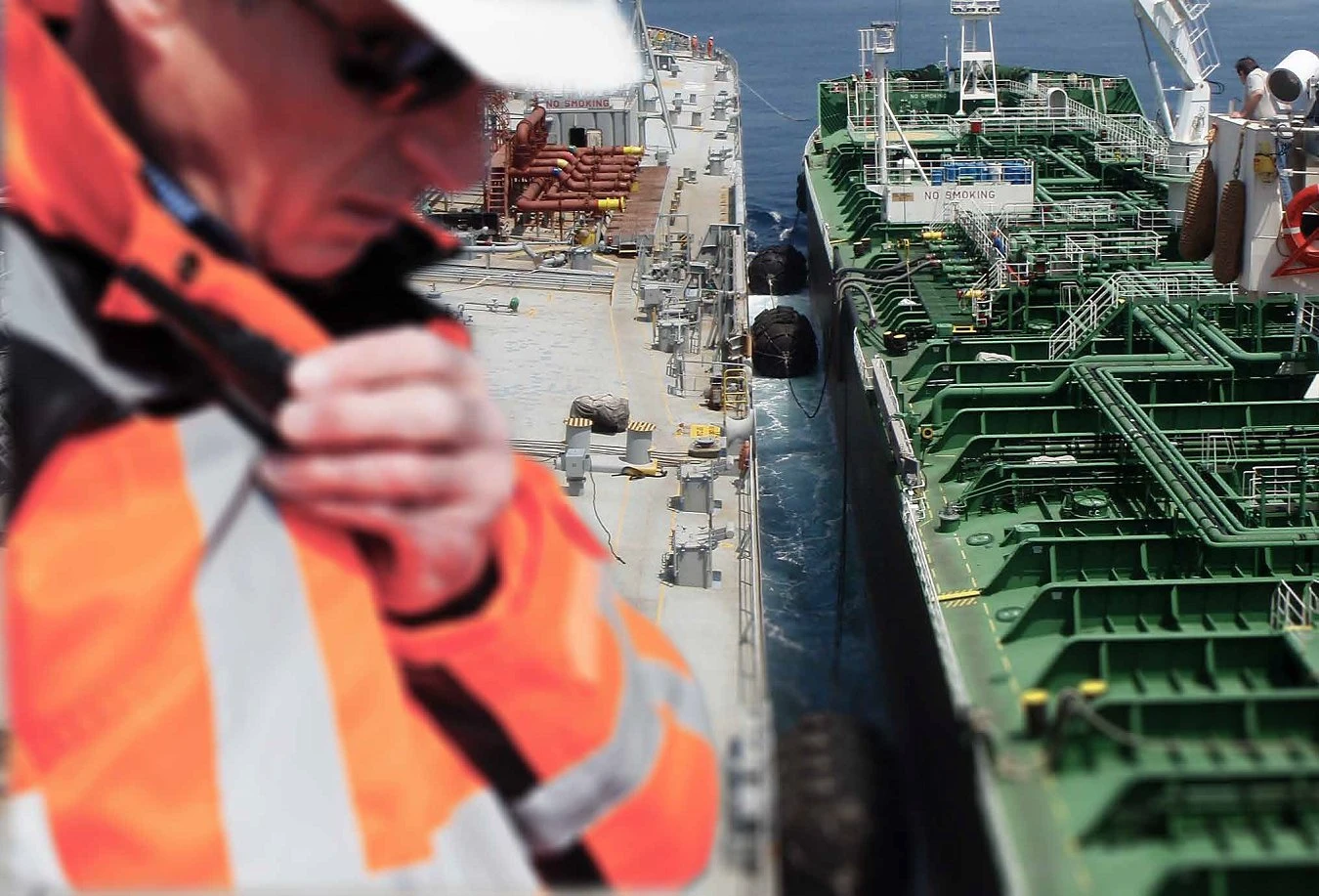

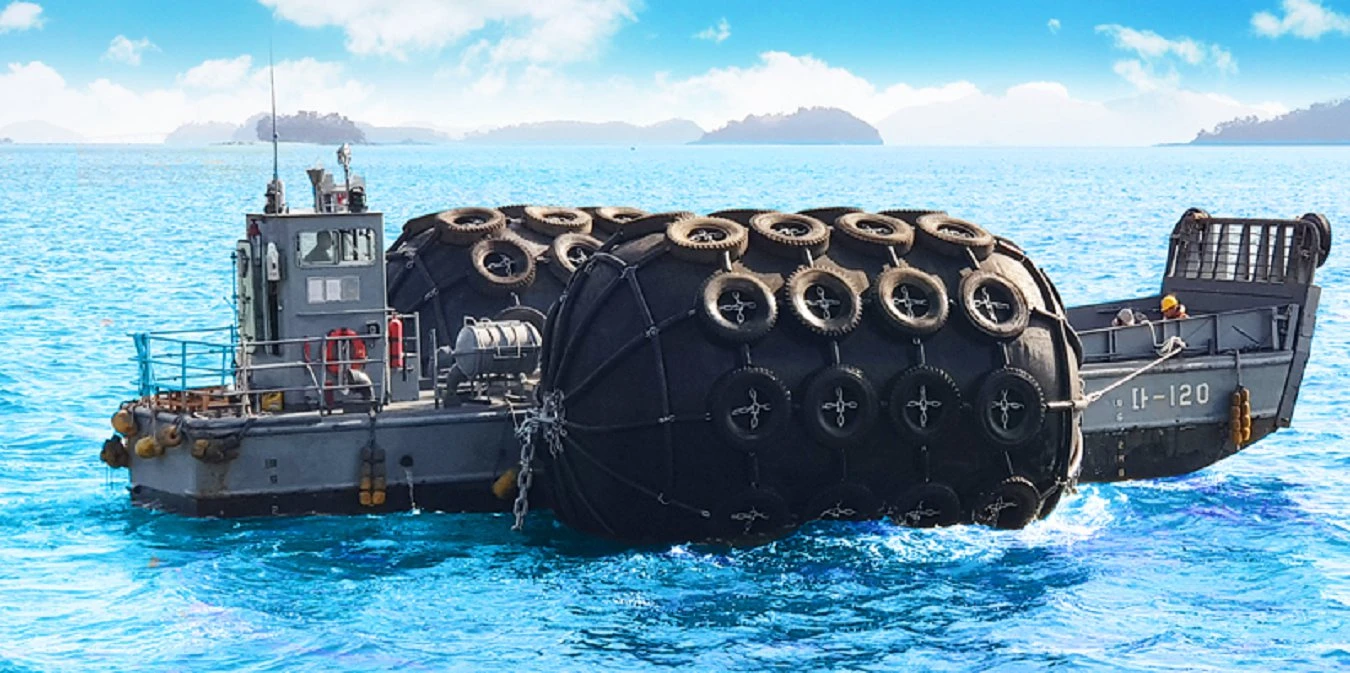

A pneumatic fender is also called a Yokohama rubber fender. It was developed by the Japanese Yokohama Rubber Company in 1958. So, it has other names: Yokohama Fender or Yokohama Pneumatic Fender. Yokohama fenders are advanced protective devices used to protect ships and terminal facilities. These Yokohama floating fenders are widely used in marine collision avoidance. When the Yokohama rubber fender is inflated, high-pressure air is injected into it, which allows the inflatable fender to float on the water. These fenders can absorb energy during ship-to-ship (STS) operations or mooring. They provide softer reaction forces to the vessel. And Yokohama fenders are lightweight and easily deflated. Their installation and redeployment are simple.

Unlike traditional elastic rubber fenders such as scrap tires or solid rubber fenders. Yokohama marine fenders have significant advantages. Such as wear-resistant, high energy absorption, low pressure per unit area of the ship, excellent impact resistance, and easy installation. The Yokohama rubber fender has a long service life and low maintenance cost. It is suitable for harsh environments. All Jerryborg Yokohama fenders are fully ISO 17357-1:2014 compliant.

Each Yokohama marine fender is equipped with a tire net and either a sling type or heavy duty chain. It is available in diameters from 500 mm to 4,500 mm and lengths from 1,000 mm to 12,000 mm, and can also be in custom sizes. They can be configured as sling-type or equipped with a heavy-duty chain and tire net for enhanced durability.

| Place of Origin | Shandong, China |

| Material | Natural Rubber |

| Product Name | Pneumatic Rubber Fender |

| Color | Black or custom |

| Usage | Boats Mooring and Ship Protection |

| Size | Customized Size |

| Initial Internal Pressure | 50Kpa 80Kpa |

| Certificate | ISO 17357、BV、SGS、CCS、DNV、ABS、LR |

| Processing Service | Vulcanization technology |

| Warranty | 24 months |

| MOQ | 1 Set |

| Packing & Delivery | Vacuum-packed, folded, and transported in containers or on pallets |