What Is Donut Fender?

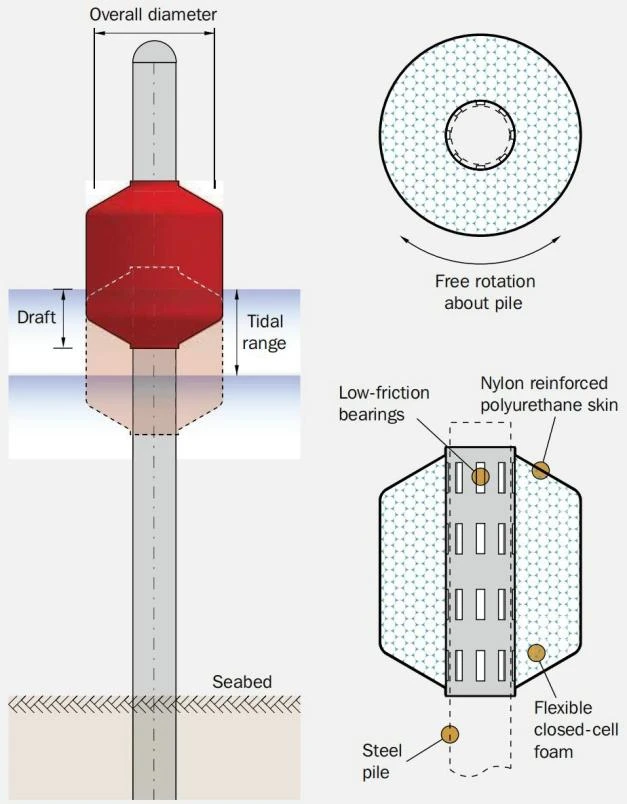

A monopile donut fender has a monopile that can be embedded in the seabed or mounted on a quay wall. Instead, the donut fender is fixed to a steel monopile and protects the vessel by moving freely with the tide.

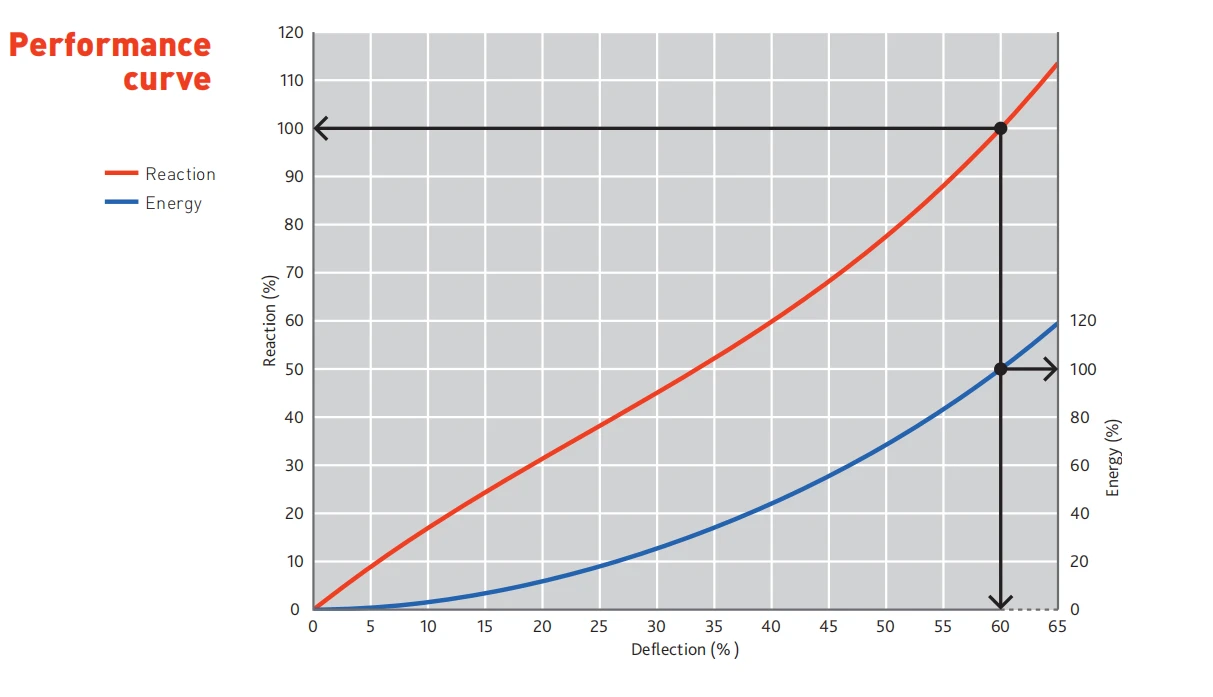

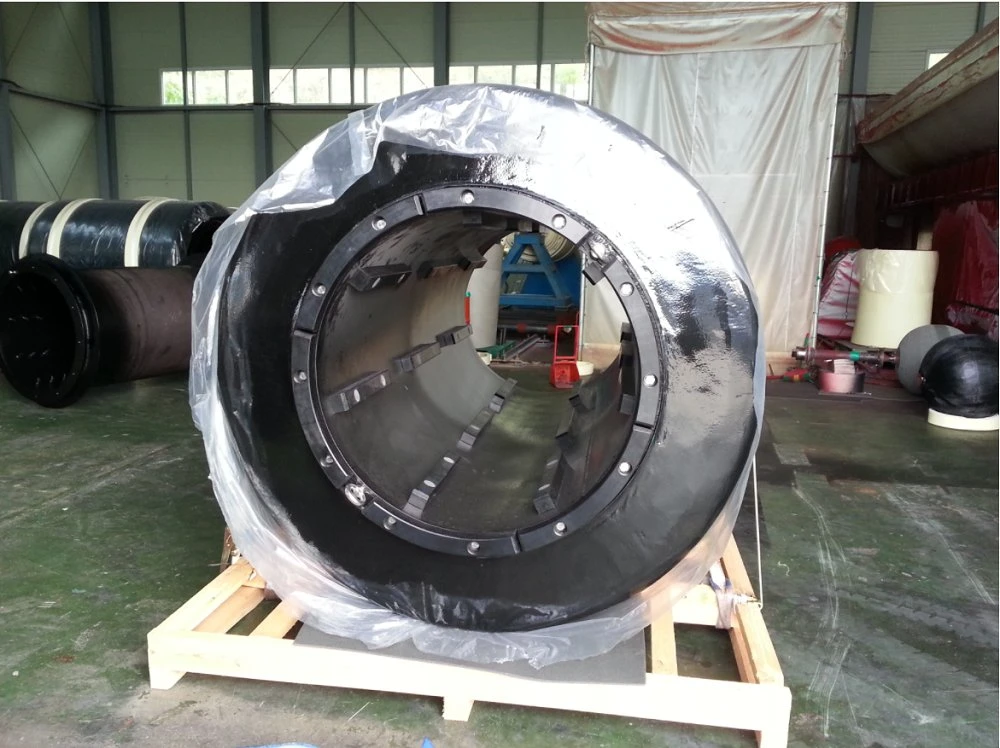

Donut fenders are similar in construction to foam filled fenders. They both have an outer shell made of polyurethane elastomer and nylon tire cord, and the inside is closed-cell foam. But donut fenders have a galvanized steel sleeve with a UHMW liner inside the sleeve. This allows the donut fender to slide along the monopile, thus protecting the vessel or guiding it through the channel.

Because of its free-moving nature, the donut fender is particularly suitable for use in areas with high tidal fluctuations. In addition, donut fenders are also ideal for use close to fairways, turns, and entrances.

Jerryborg Marine’s donut fenders are available in standard sizes and customized sizes for your needs. You can also install mooring points or auxiliary fenders on top of the donut fenders!