Jerryborg Marine Airbags

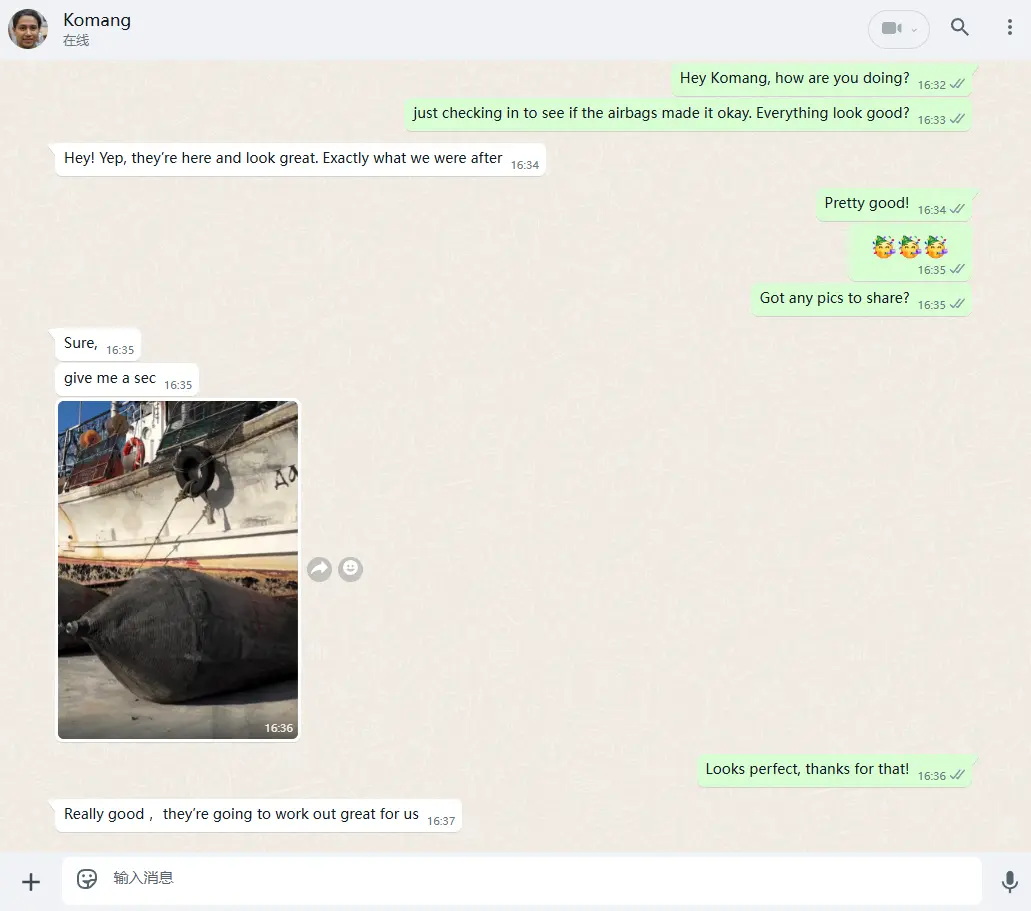

A marine rubber airbag is based on the log rolling method, using soft rubber for lifting and bearing. It is an innovative product with independent intellectual property rights in China. It is widely used in the fields of heavy lifting, ship launching and upgrading, caisson lifting, and underwater engineering buoyancy aid. Marine rubber airbags are not restricted by space and heavy machinery, which can effectively shorten the construction period and save much money.

Marine Rubber Airbags Application

1. Ship Launching and Upgrading

After more than 20 years of development in China, marine rubber airbags have proved to be the most reliable and stable technology for ship launching and upgrading. It is suitable for tonnage flatbed to 10,000 tonnes giant ships. Meanwhile, foreign shipyards, dockyards, and port construction companies also widely recognized marine rubber airbags. The ship launching and upgrading technology of marine rubber airbags has also been vigorously promoted in America, Europe, Southeast Asia, and other markets.

2. Lifting and Moving

Marine rubber airbags can be used for lifting, launching, moving, and transporting caissons in harbor construction works.

3. Buoyancy Salvage

Due to the buoyancy and carrying capacity of marine rubber airbags, they are also widely used in wreck salvage and buoyancy rescue.