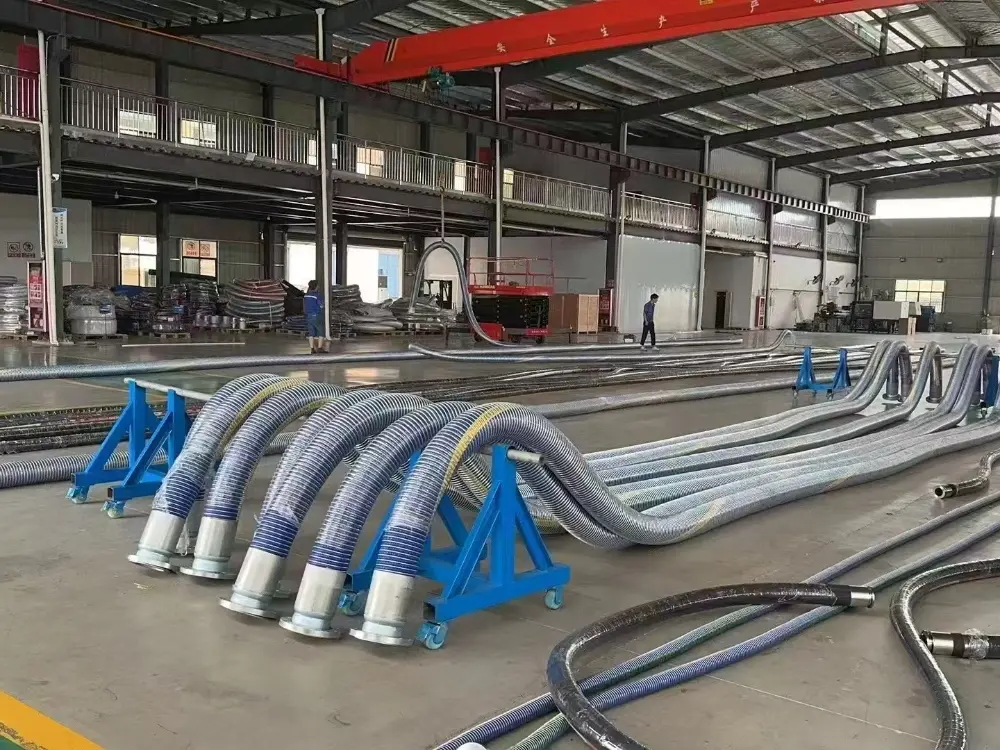

Composite Hose Construction

Composite hose is manufactured from multiple layers of thermoplastic fabrics & films that are spirally wrapped and supported by internal & external wire helices, and it is a component of fluid transportation.

The multiple material layers make the structure of the hose firm, thus making it pressure-resistant. The high-grade material used for making composite hoses also provides greater safety, which makes composite hoses widely used in industry areas.

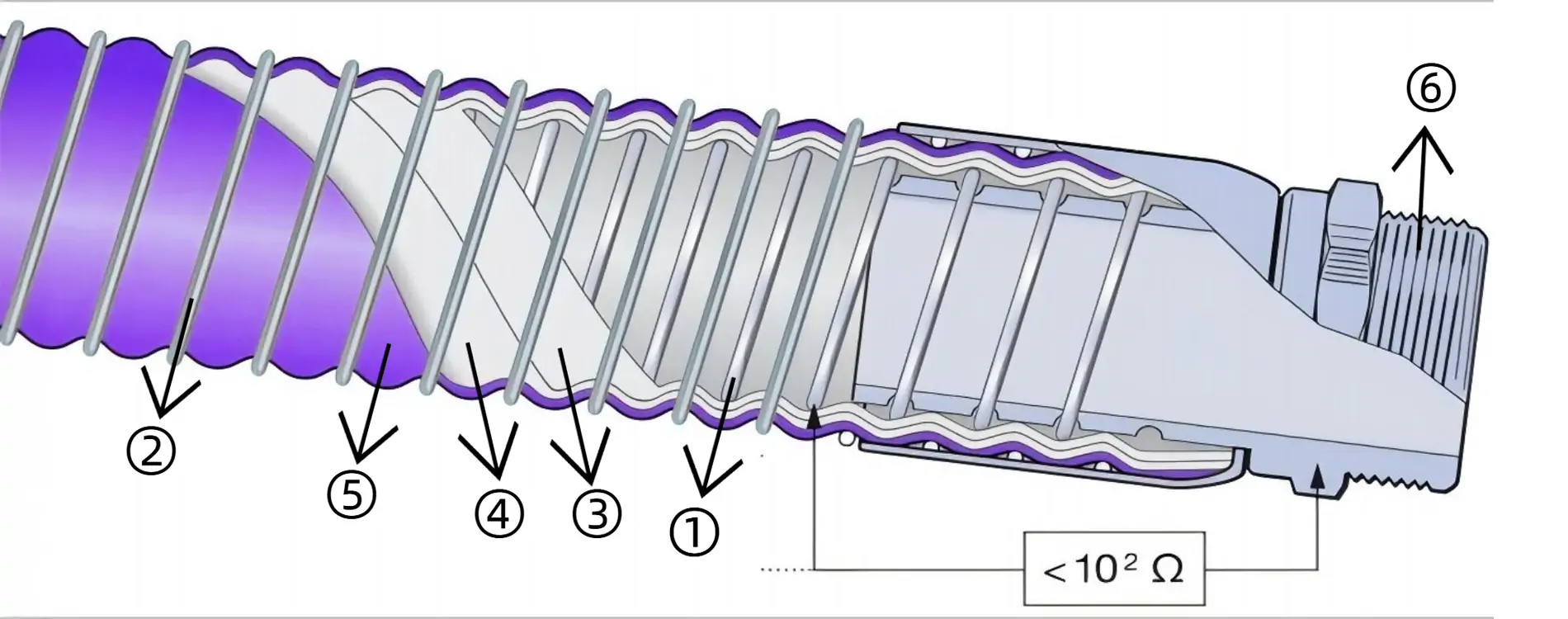

1. Internal Helical Wire:

According to the characteristics of the hose transferring medium, different materials are available: stainless steel wire, galvanized steel wire, and aluminum alloy wire (PP, PVDF-covered steel wire).

2. External Helical Wire:

Galvanized steel wire, stainless steel wire, PP-coated steel wire.

3. High Resistance Inner Wire:

The quality of the hose plays a key role in the chemical aggressiveness and chemical liquid barrier, according to the characteristics of different media to choose

4. Reinforcement Layer:

It consists of a multi-layer functional polymer film and a synthetic fabric reinforcement layer, then spirally wrapped and supported by internal & external wire helices.

5. Anti-aging outer layer:

The outer layer is made of water proof and abrasion-resistant PVC fabric, which is highly resistant to corrosive chemicals and hydrocarbons. Applicable temperatures from 200 °C to +200°C(-328°F to +392°F), it is light, safe, tough, corrosion resistant, temperature resistant, weather resistant, and other characteristics.

6. Hose Couplings:

Jerryborg offers more professional and reliable connection solutions for hose coupling systems; according to different media, we can provide brass, aluminum, stainless steel, PP, and other material hose coupling.