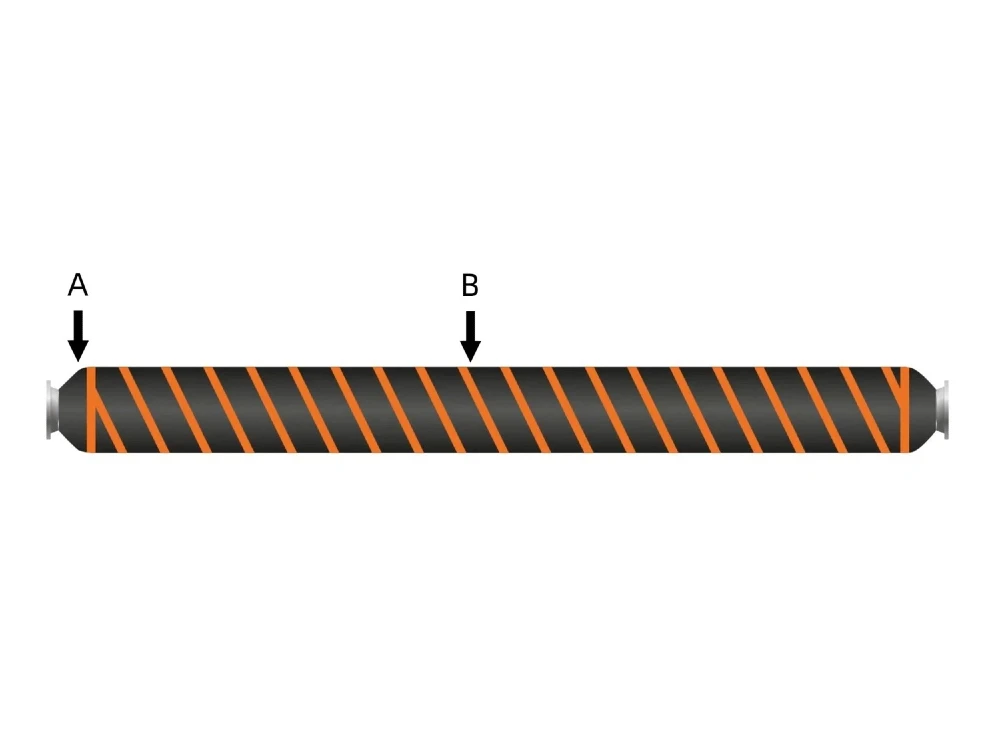

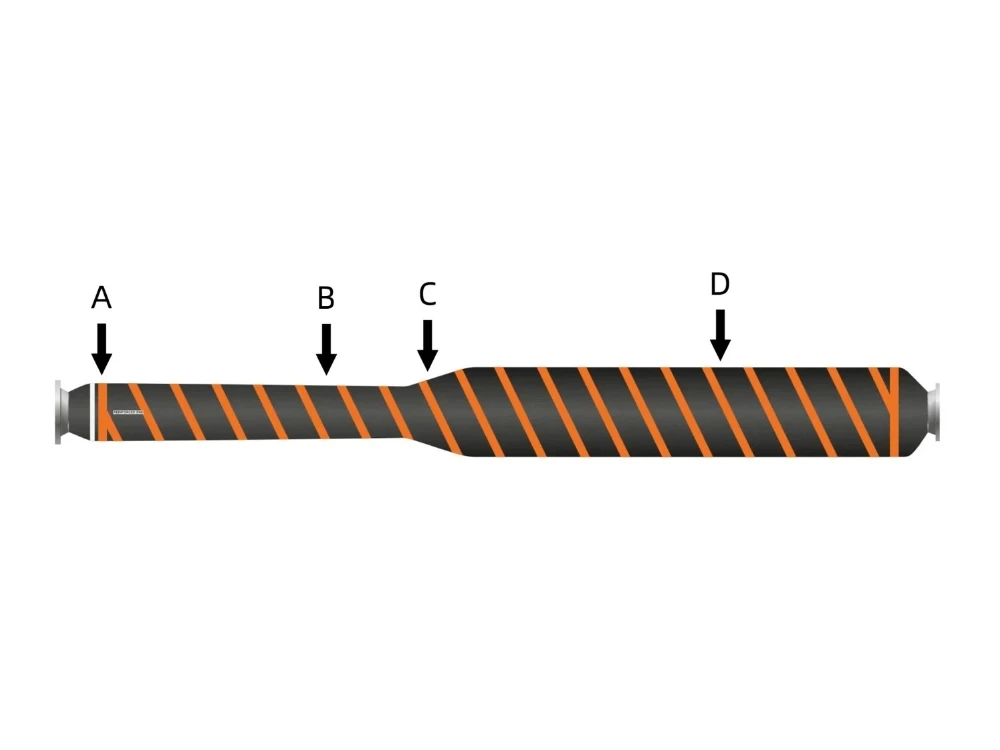

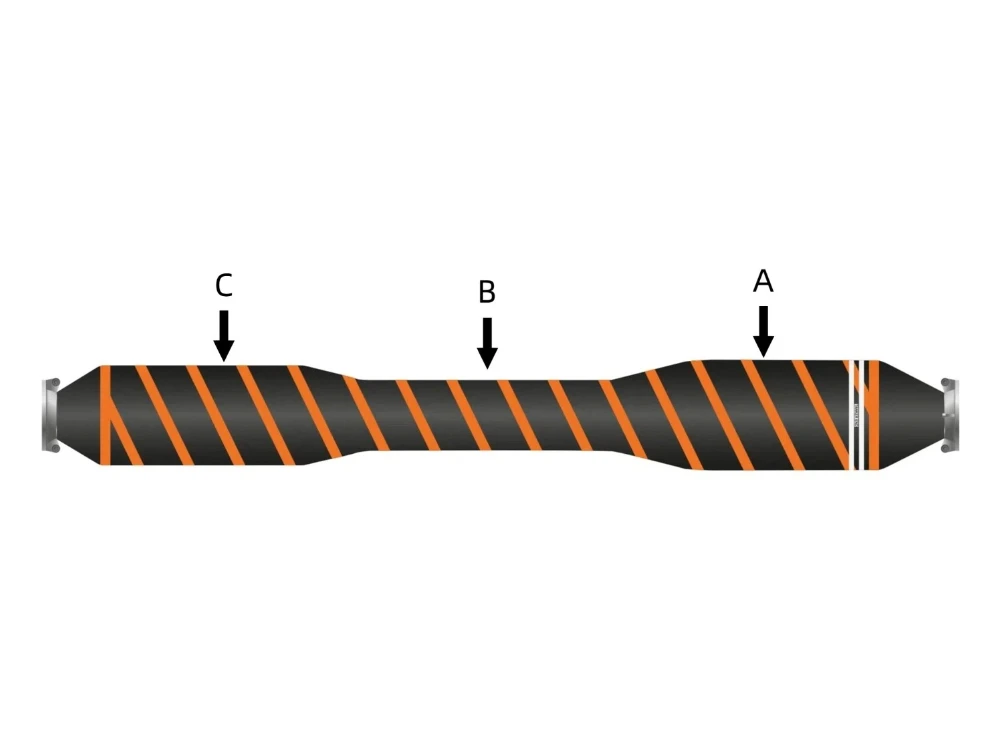

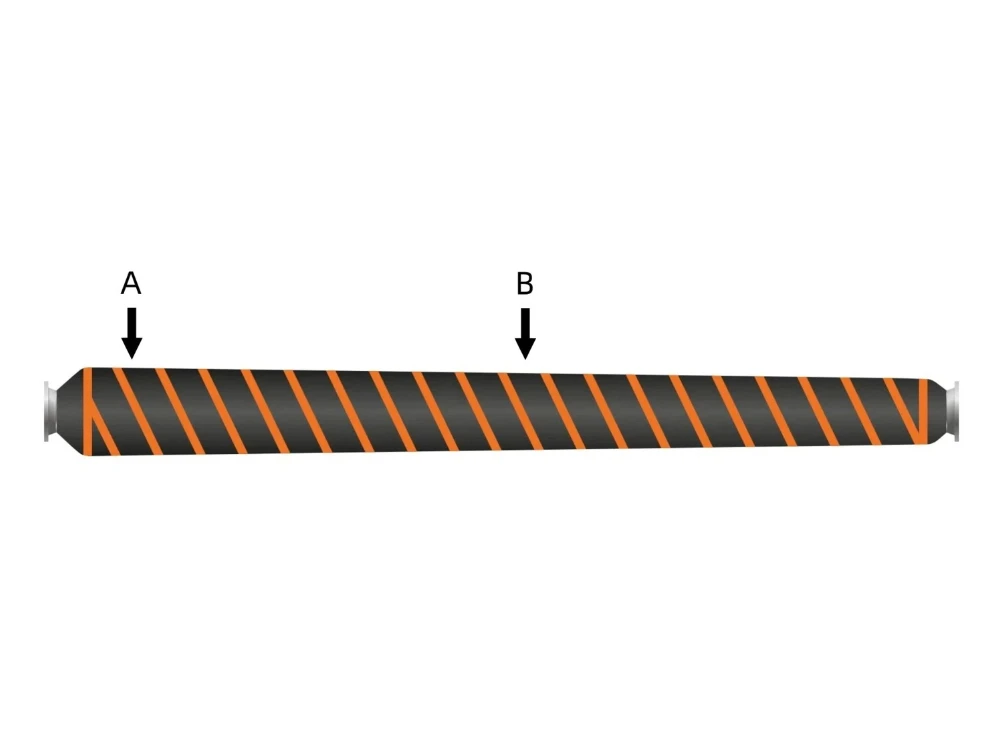

Jerryborg Floating Oil Hoses

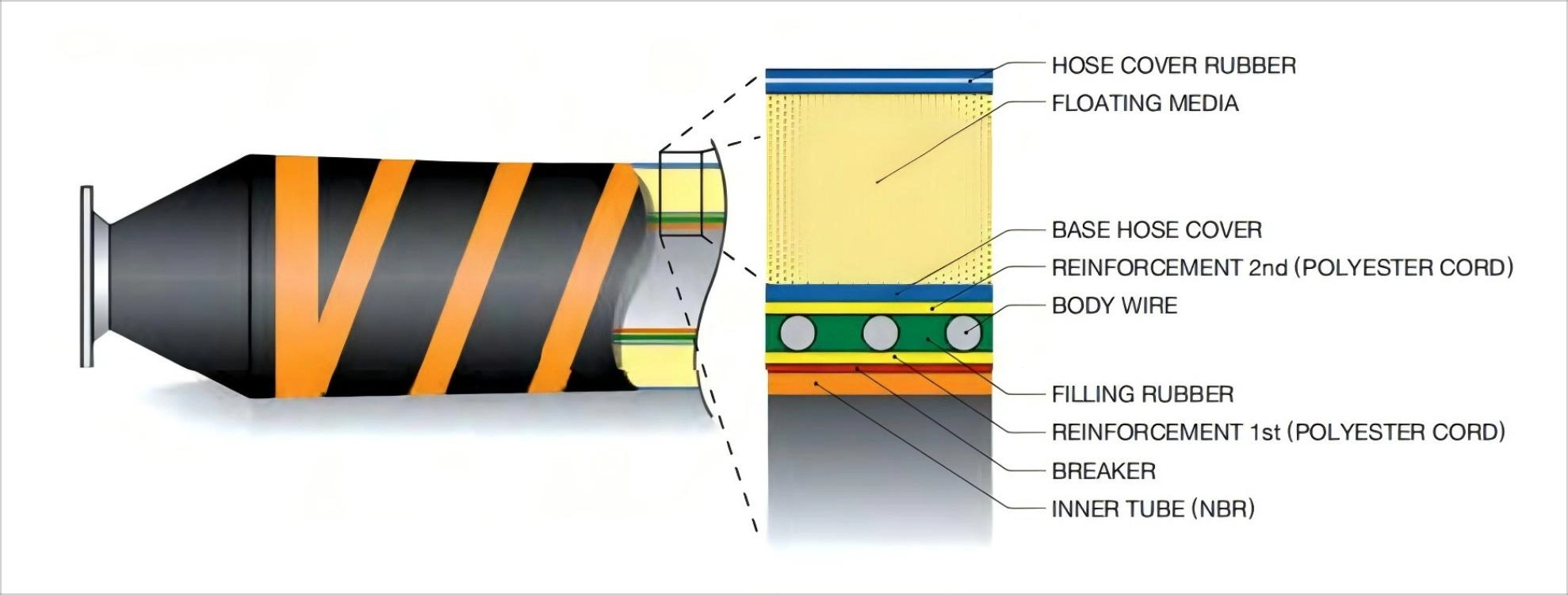

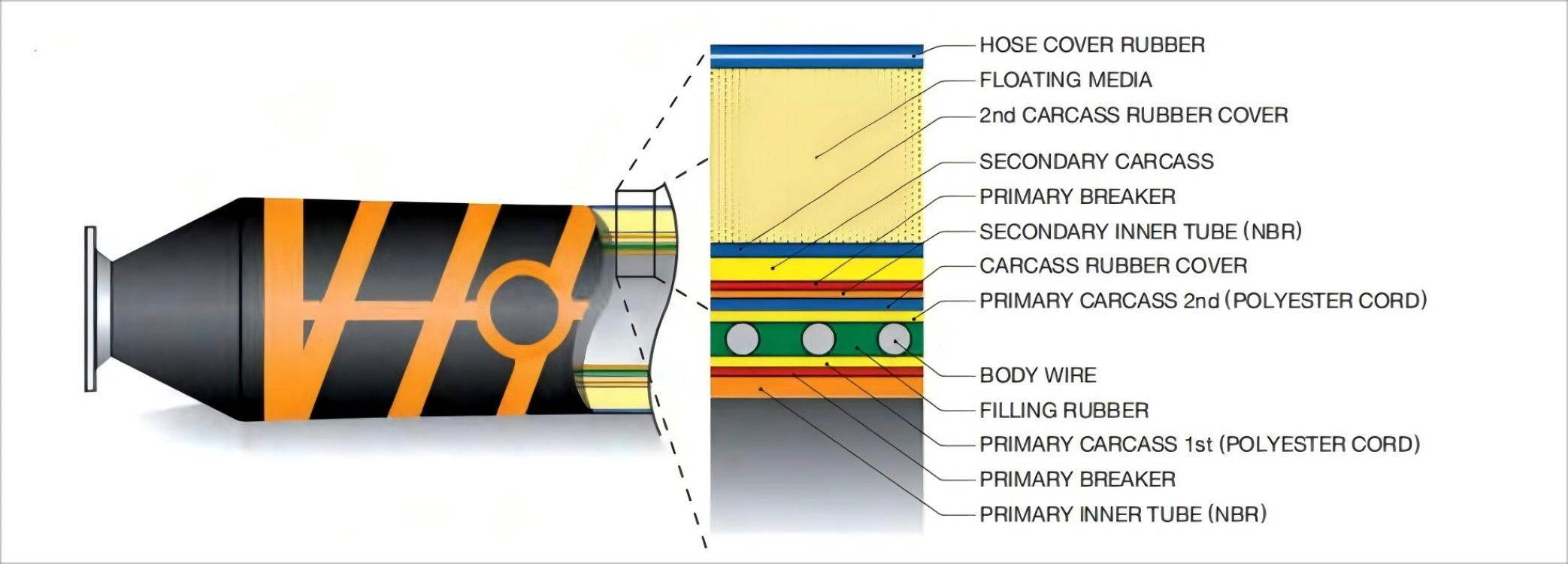

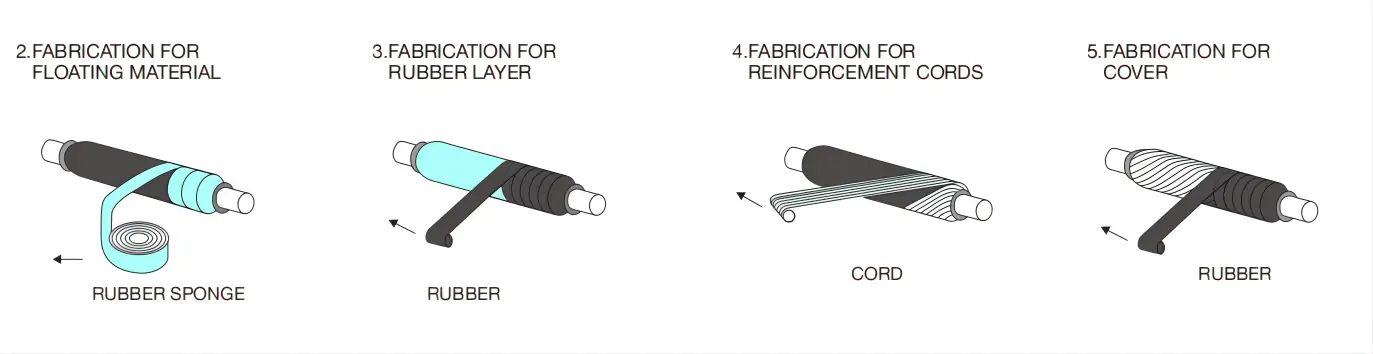

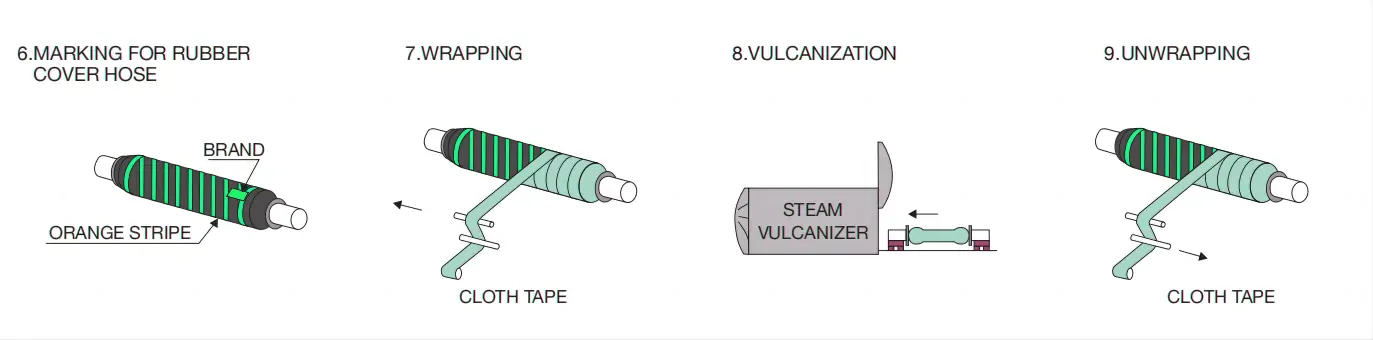

Jerryborg Marine floating oil hose is designed for offshore oil discharge. It is a self-floating hose that transfers crude oil and petroleum products from offshore vessels and mooring systems. The floating oil hose is suitable for most media, such as oil (up to 50 percent aromatic content), water, brine, barite, cement, etc.

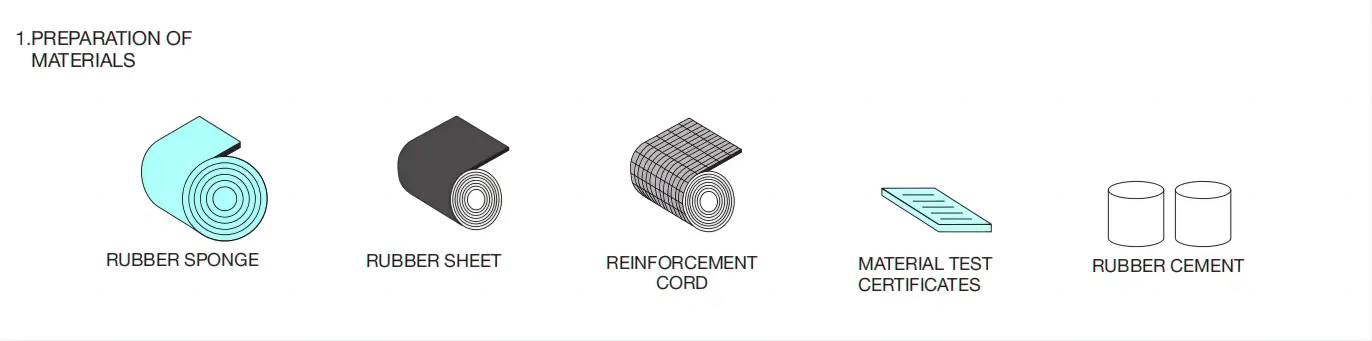

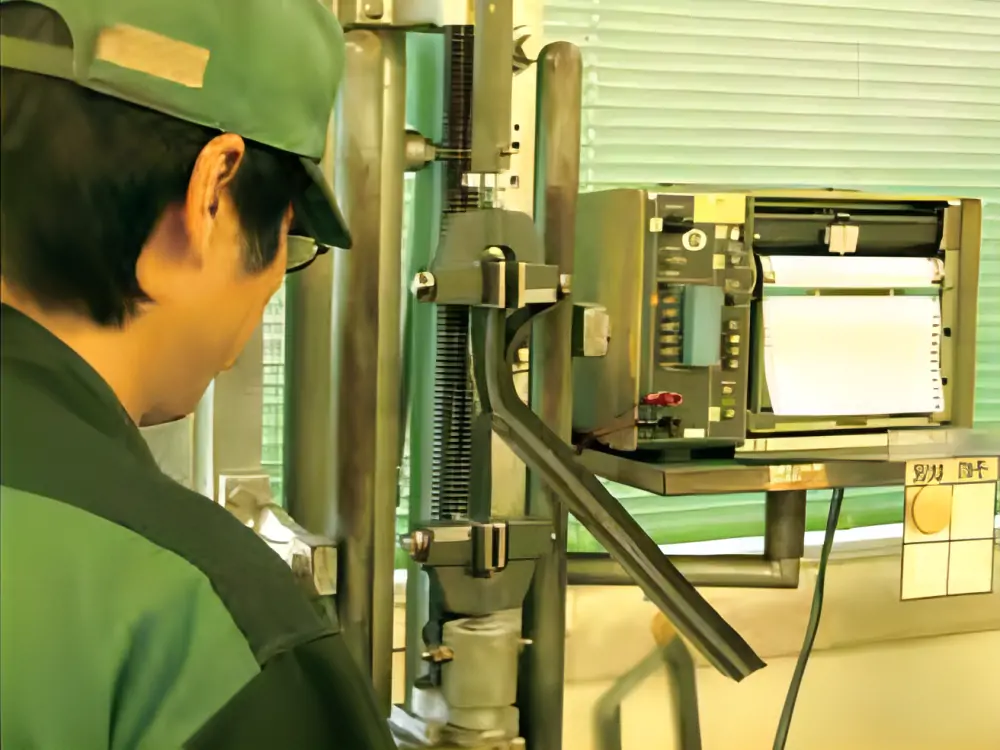

Jerryborg Marine floating oil hoses are designed and produced in full compliance with OCIMF standards. Our marine floating oil hoses are manufactured and tested in accordance with the requirements of ISO 9001:2015 quality standards.