Jerryborg STS Hose

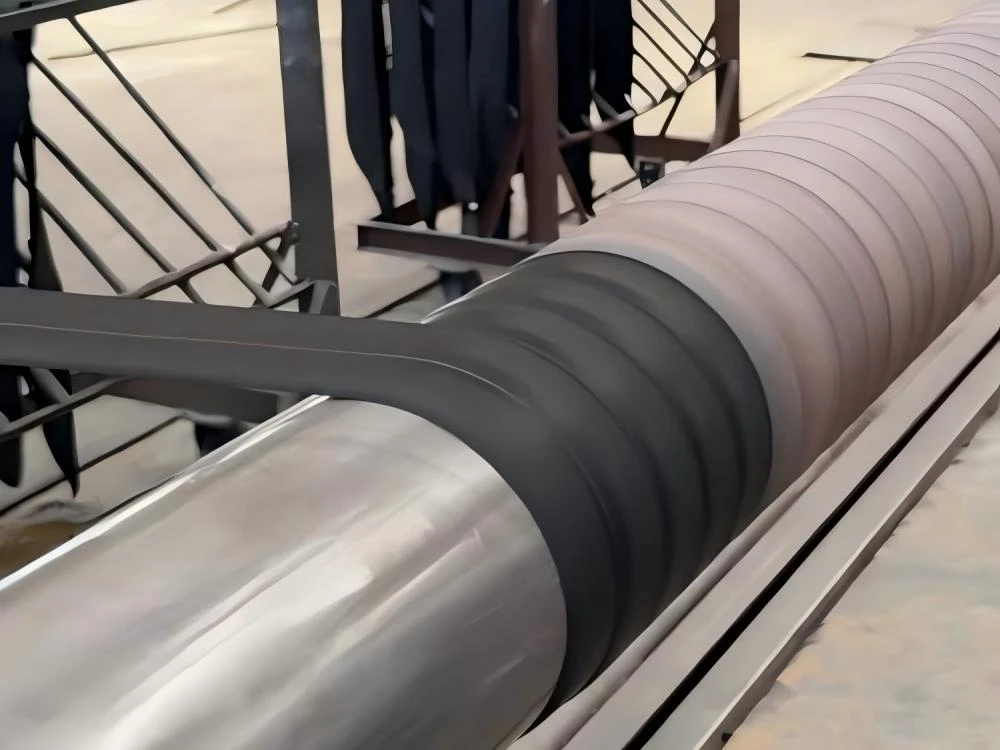

STS hose is a flexible rubber hose used for ship-to-ship transport of crude oil, light oil, and petroleum-based fluid media. These crude oil hoses are often used in harsh conditions, leading to rapid deterioration and rapid wear and tear, so choosing a high-quality brand of STS hose will be faster, more reliable, and safer.

Jerryborg Marine’s top-of-the-range STS flexible cargo oil hoses have outstanding features that provide safety and reliability in various demanding situations. All Jerryborg Marine STS flexible hoses are designed to EN 1765 standards.