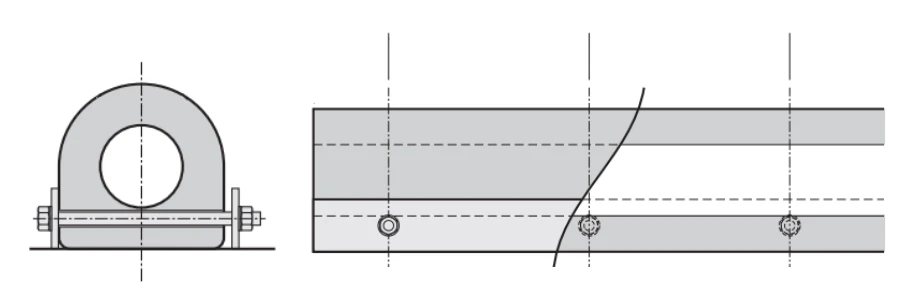

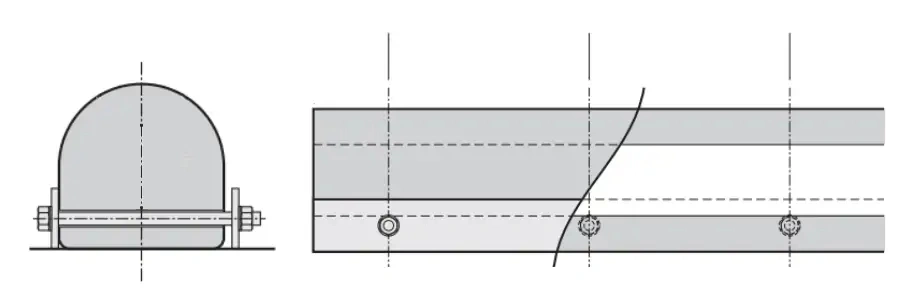

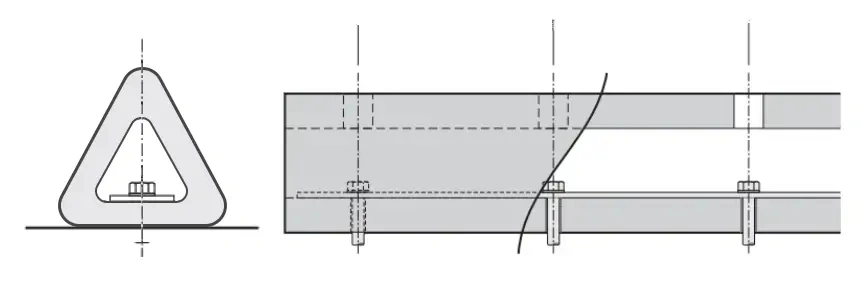

Jerryborg Marine D Fenders

Jerryborg Marine specializes in crafting diverse D-type rubber fenders that exhibit remarkable impact resistance. These d-fenders come in many shapes and sizes, catering to various applications and needs. We offer hollow and solid options, spanning dimensions from 20mm to 500mm. For your specific requirements, we ensure a custom rubber fender solution.

D rubber fenders have soared in popularity owing to their versatility and top-notch protective qualities. These d-type fenders can be safely attached to various surfaces using bolts. Jerryborg Marine pre-drills many D fenders for even bolt spacing, cutting installation time. We also offer custom d fenders, like pre-curving, chamfering, or cutting to exact lengths.

Get a Quote