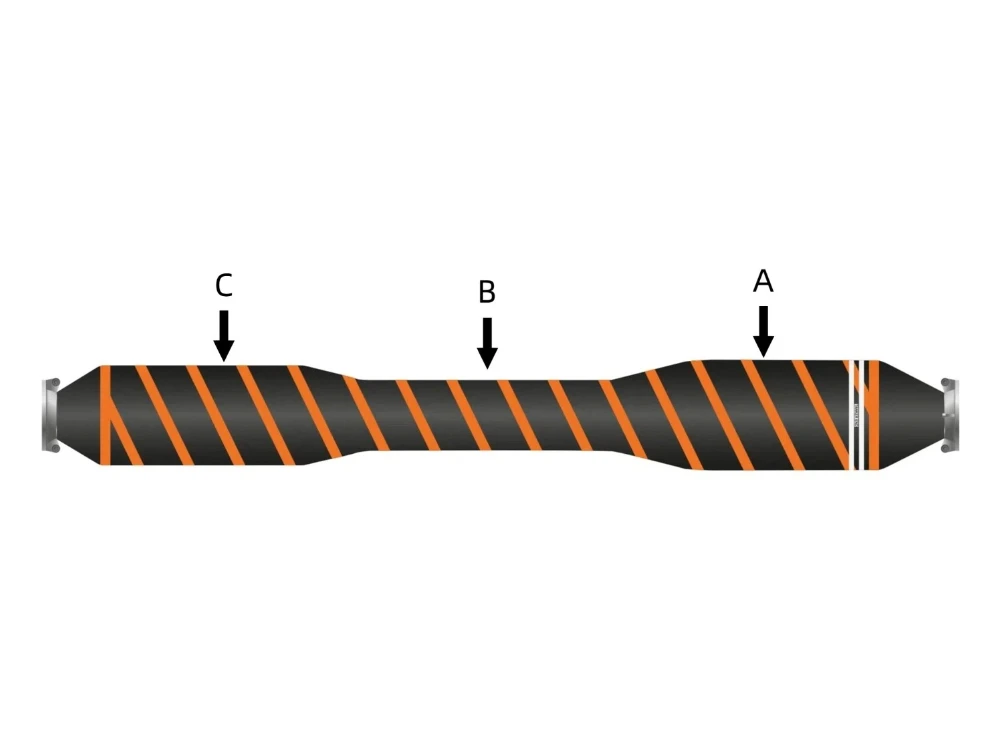

Tanker Rail Full Dumbbell Floating Hose

Tanker rail full dumbbell floating hose is installed on the side of the ship. It is used to connect with the pipeline end manifolds of a floating production, storage, and offloading unit. This connection allows safe and smooth transfer of crude oil and petroleum products.

Tanker Rail Full Dumbbell Floating Hose Testing

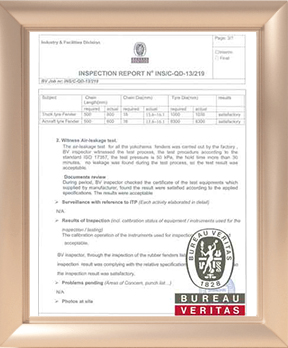

Jerryborg Marine can manufacture and test floating hoses according to the GMPHOM 2009 (OCIMF) standard or customer-specified standards.

Get A Quote