Ⅰ、SHIP TO SHIP

1.SHIP TO SHIP TRANSFER HOSES

STS hoses typically refer to Composite Hose. They are used in the context of Ship-to-Ship (STS) transfer operations. STS transfer involves the transfer of various substances. Examples include oil, chemicals, or liquefied natural gas (LNG). The transfer occurs between two vessels positioned side by side on the water. A series of extended testings has proven something. It has proven that Jerryborg Marine STS composite hoses are reliable and safe to use. In tough offshore conditions, our STS hoses have a high resistance against any damage. This is due to strong construction and high-quality material adopted.

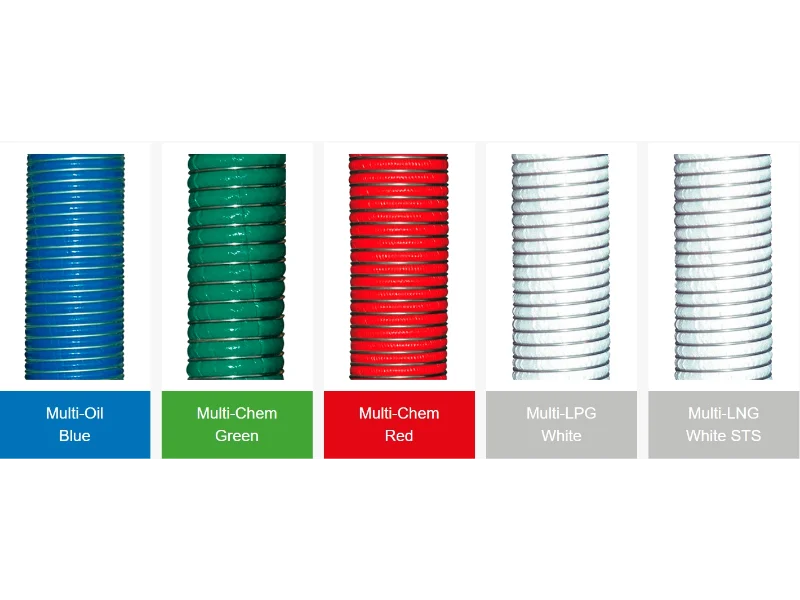

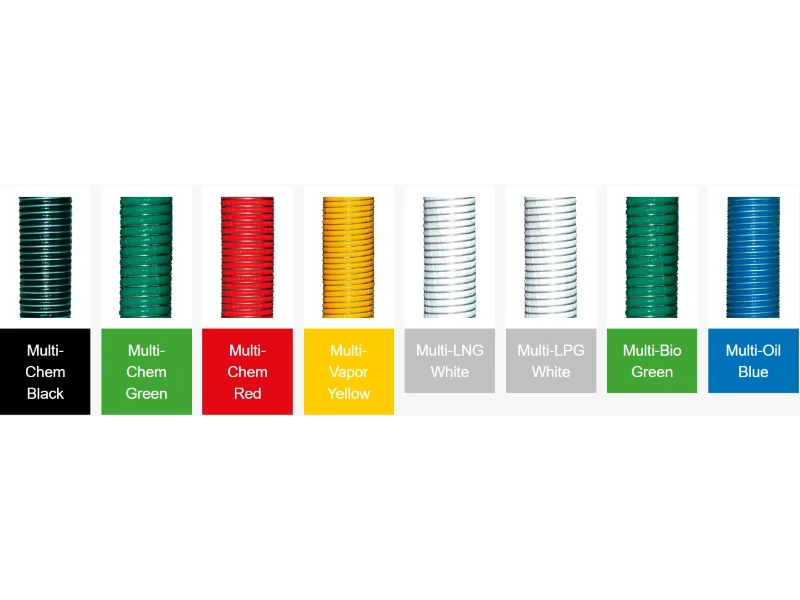

2.CHOOSE YOUR COMPOSITE HOSE

(1)Multi-Oil Blue:

(1)Multi-Oil Blue:

(2)Multi-Chem Green:

Typically, design green composite hoses for transferring chemical products, including corrosive and aggressive chemicals. Commonly, these hoses handle substances that are corrosive and aggressive. Jerryborg produces the hose with extra layers to withstand extreme conditions. We produce our Multi-Chem Green hoses to international standards and certify them to regulations like EN 13765, IMO BC, and PED.

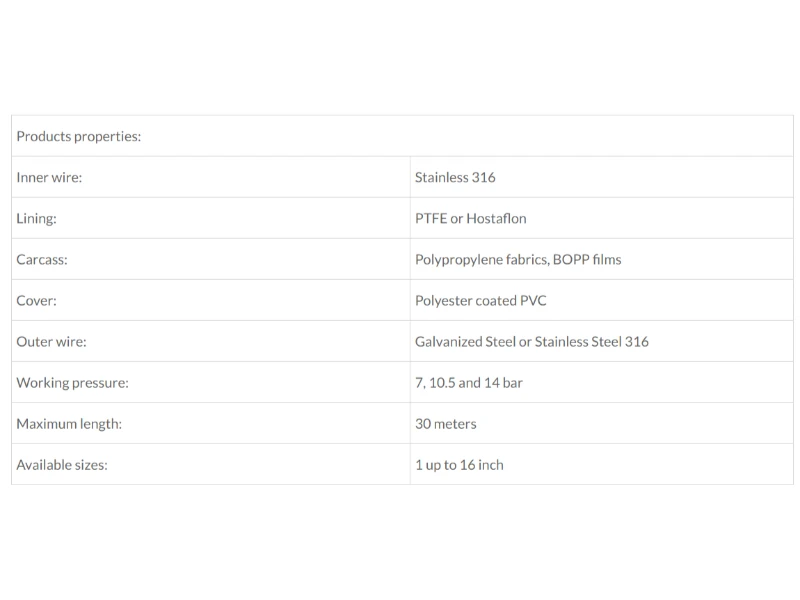

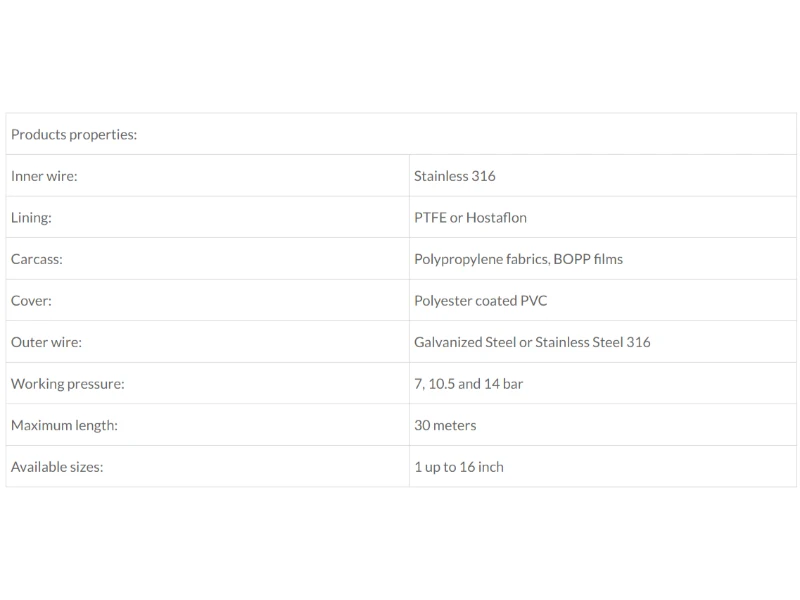

(3)Multi-Chem Red:

Multi-Chem Red hoses are designed for handling highly corrosive chemicals and acids. These hoses have special engineering. They are suitable for a wide range of chemicals. This is due to their internal stainless steel wire reinforcement and PTFE or Hostaflon lining. They can handle most known chemicals effectively. They maintain their integrity even at temperatures of up to 100°C. Jerryborg Multi-Chem Red hoses are produced and certified to international standards. These standards include EN 13765, IMO IBC, and PED regulations.

(4)Multi-LPG White:

Multi-LPG White hoses are designed for safely transporting fully refrigerated substances. They can operate in extremely cold conditions, as low as -50°C, on ships, barges, and marine terminals. These hoses are versatile and can effectively handle various products. The range includes Ammonia, Butane, Propane, and extreme-cold applications like Liquid Ethylene at -105°C and Liquid Ethane at -88°C.

(5)Multi-LNG White STS:

Ⅱ、SHIP TO SHORE

1.SHIP TO SHORE HOSES

Ship-to-Shore operations need high-quality composite hoses. These operations deal with challenging maritime conditions and tough handling at terminals. The hoses follow industry standards like EN 13765 / EN 13766 (ISO 27126 / 27127). And hoses also follow international terminal guidelines such as ISGOTT .

Jerryborg composite hoses follow Pressure Equipment Directive guidelines (PED 2014/68/EU). DNV, Bureau Veritas, and Lloyd’s Register carefully examine and certify these products. This ensures strict compliance with specified standards.

2.CHOOSE YOUR COMPOSITE HOSE

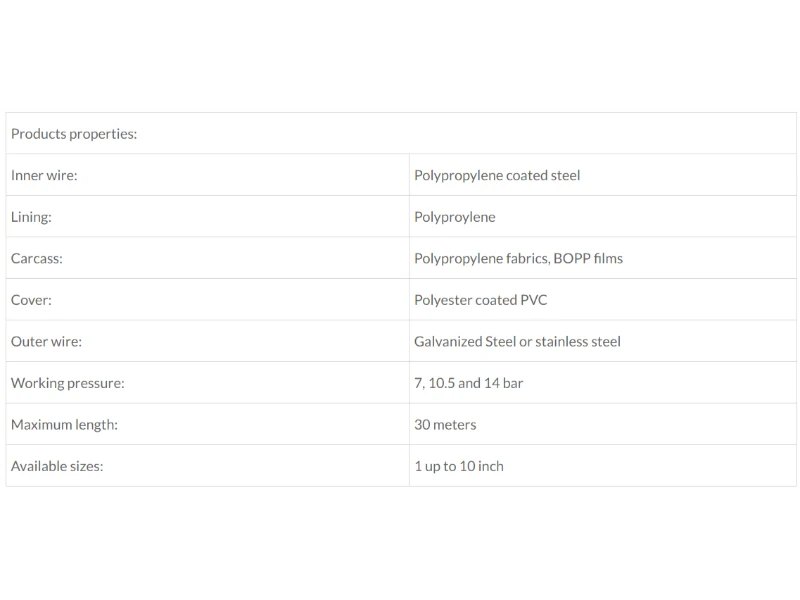

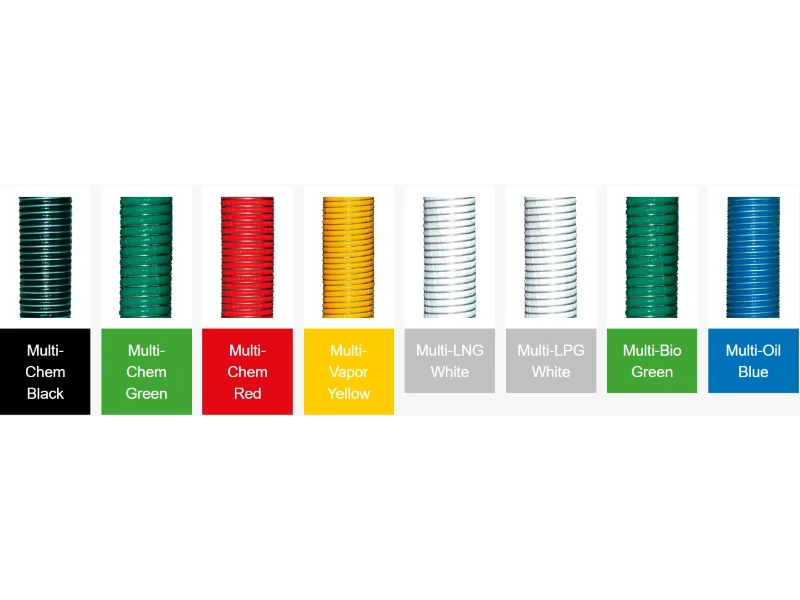

(1)Multi-Chem Black:

Multi-Chem Black hoses are designed for corrosive chemicals :

- Chlorine

- Hydrochloric Acid

- Sulfuric Acid.

They have an inner wire coated in Polypropylene, along with layers of fabric and films.

Jerryborg Multi-Chem Red hoses meet International standards like EN 13765, IMO IBC, and PED regulations. They are crafted and certified for various applications.

(2)Multi-Chem Green:

Green hoses are made for transferring various chemicals, including corrosive and aggressive ones. They handle these substances well. Jerryborg hoses have special layers for extreme conditions. Our Multi-Chem Green hoses meet international standards like EN 13765, IMO BC, and PED regulations.

(3)Multi-Chem Red:

Red hoses by Jerryborg are made to handle strong chemicals. They work well with various substances, thanks to their internal stainless steel wire and special lining. These hoses can handle most chemicals and remain intact even at temperatures up to 100°C.

Jerryborg Multi-Chem Red hoses meet international standards like EN 13765, IMO IBC, and PED regulations.

(4)Multi-Vapor Yellow:

Multi-Vapor Yellow hoses recover chemical and Hydrocarbon vapors on ships, barges, and terminals. They contain Galvanized Steel or Polypropylene-coated Steel wire and a Polypropylene lining. These hoses resist vacuum, are lightweight, and flexible. Jerryborg Multi-Vapor Yellow hoses comply with standards like EN 13765, IMO IBC, and PED.

(5)Multi-LNG White:

Multi-LNG White hoses handle extremely cold conveyants, down to -196°C. They suit applications like Liquid Nitrogen and LNG. Two main variants exist:

- Multi-LNG White for LNG bunkering, Ship-to-Shore transfers, and industrial use.

- Multi-LNG White STS for Ship-to-Ship operations and LNG Bunker activities.

(6)Multi-LPG White:

Multi-LPG White hoses handle fully refrigerated conveyants, reaching -50°C. Ideal for ships, barges, and marine terminals, these hoses are versatile. They can accommodate products like Ammonia, Butane, and Propane.

They also transport Liquid Ethylene at -105°C and Liquid Ethane at -88°C. Jerryborg Multi-LPG White hoses meet international standards like EN 13766 & IMO IGC.

(7)Multi-Bio Green:

Multi-Bio Green hoses smoothly convey Bio-Diesel. The lining resists Esterified Vegetable Oils. Jerryborg Multi-Bio Green hoses meet EN 13765, IMO IBC, and PED standards.

(8)Multi-Oil Blue:

Blue composite hoses transfer oils in industries and maritime settings. They handle crude oil, petrochemicals, and diesel. Jerryborg Multi-Oil Blue hoses meet EN 13765, IMO IBC, and PED standards.

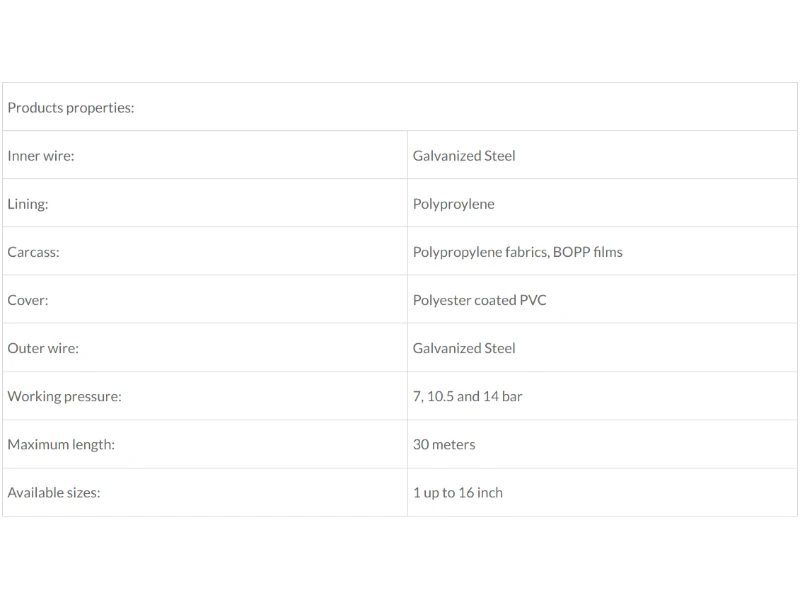

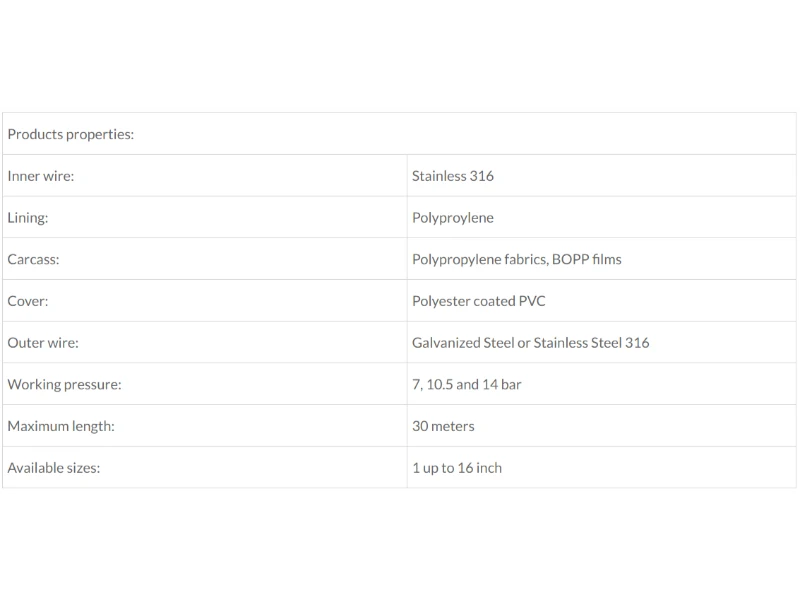

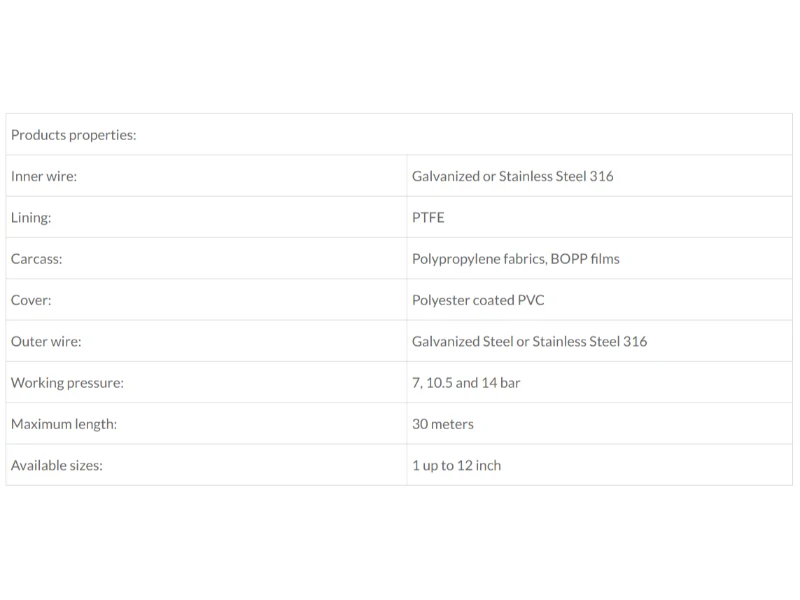

| Products properties: | |

| Inner wire: | Galvanized Steel |

| Lining: | Polyproylene |

| Carcass: | Polypropylene fabrics, BOPP films |

| Cover: | Polyester coated PVC |

| Outer wire: | Galvanized Steel |

| Working pressure: | 7, 10.5 and 14 bar |

| Maximum length: | 30 meters |

| Available sizes: | 1 up to 16 inch |

Ⅲ、INDUSTRIAL

1.INDUSTRIAL HOSES

- rail and tank car loading

- plant service, mixing stations

- drum filling

- pump operations

Ⅳ、SPECIALS

1.SPECIALS COMPOSITE HOSES

We tailor solutions for various industrial needs. Our focus includes high-temperature transfers, rail car loading/unloading, fire-safe applications, and ATEX-regulated zones. These applications cover LNG bunkering, heavy crude hoses, and high-temperature hoses. Jerryborg Composite Hoses adhere to recently developed standards, such as EN 1474-II, EN 12434, and PGS33-2, proving their effectiveness before official release.

2.CHOOSE YOUR COMPOSITE HOSE

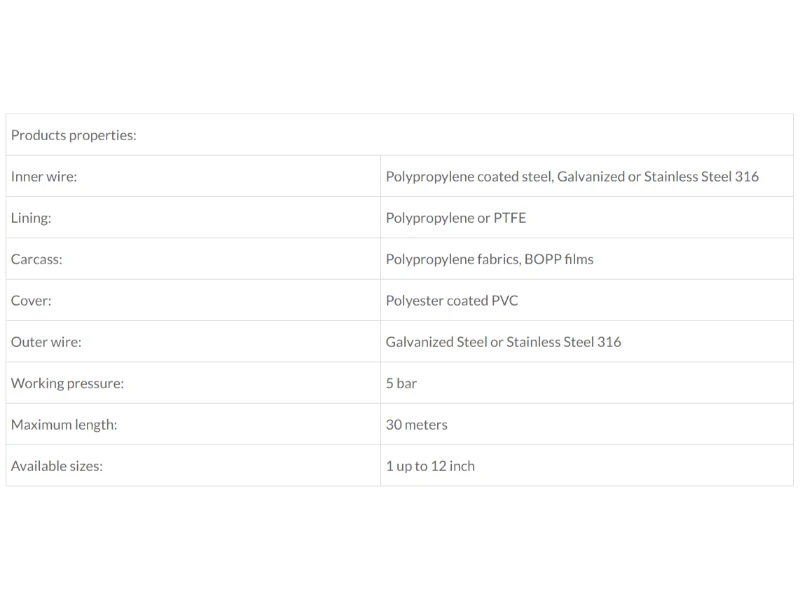

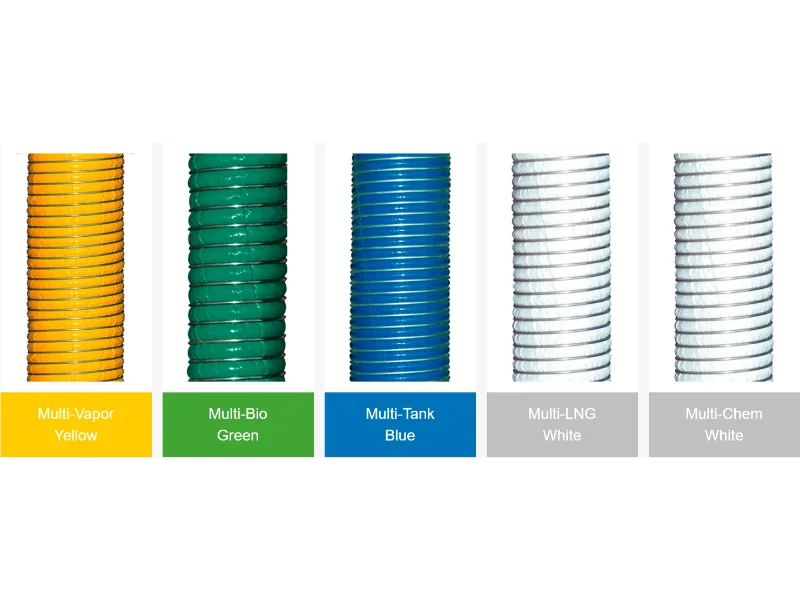

(1)Multi-Vapor Yellow:

Multi-Vapor Yellow hoses are for chemical and Hydrocarbon vapor recovery on ship, barge, and terminal operations. These hoses have Galvanized Steel or Polypropylene-coated Steel internal wires and a Polypropylene lining. Multi-Vapor hoses can withstand vacuum, have a lightweight build, and offer exceptional flexibility. Jerryborg Multi-Vapor Yellow hoses meet international standards, including EN 13765, IMO IBC, and PED regulations.

| Products properties: | |

| Inner wire: | Polypropylene coated steel, Galvanized or Stainless Steel 316 |

| Lining: | Polypropylene or PTFE |

| Carcass: | Polypropylene fabrics, BOPP films |

| Cover: | Polyester coated PVC |

| Outer wire: | Galvanized Steel or Stainless Steel 316 |

| Working pressure: | 5 bar |

| Maximum length: | 30 meters |

| Available sizes: | 1 up to 12 inch |

(2)Multi-Bio Green:

Jerryborg engineers Multi-Bio Green hoses for the seamless conveyance of continuous Bio-Diesel products. These hoses feature a lining material that remains unaffected by the Esterified Vegetable Oils present in Bio-Diesel products. Jerryborg produces and certifies Multi-Bio Green hoses to international standards like EN 13765, IMO IBC, and PED regulations.

| Products properties: | |

| Inner wire: | Galvanized or Stainless Steel 316 |

| Lining: | PTFE |

| Carcass: | Polypropylene fabrics, BOPP films |

| Cover: | Polyester coated PVC |

| Outer wire: | Galvanized Steel or Stainless Steel 316 |

| Working pressure: | 7, 10.5 and 14 bar |

| Maximum length: | 30 meters |

| Available sizes: | 1 up to 12 inch |

(3)Multi-Tanktruck Blue:

Multi-Tanktruck Blue hoses are designed for transporting Hydrocarbons and aromatics in tank truck applications. They’re known for flexibility, light weight, and easy handling. These hoses include both Galvanized Steel and Aluminum wires. The design pressure is 10.5 bars and a safety factor of 4:1. They meet international standards such as EN 13765, AS 2683, and BS 3492 for production and testing.

| Products properties: | |

| Inner wire: | Galvanized Steel or Aluminum |

| Lining: | Polyproylene |

| Carcass: | Polypropylene fabrics, BOPP films |

| Cover: | Polyester coated PVC |

| Outer wire: | Galvanized Steel |

| Working pressure: | 10.5 bar |

| Maximum length: | 30 meters |

| Available sizes: | 1 up to 4 inch |

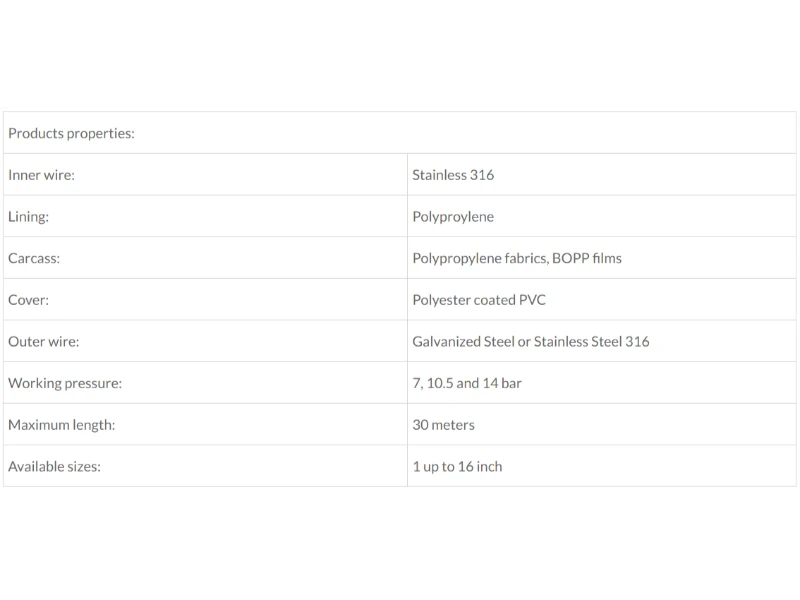

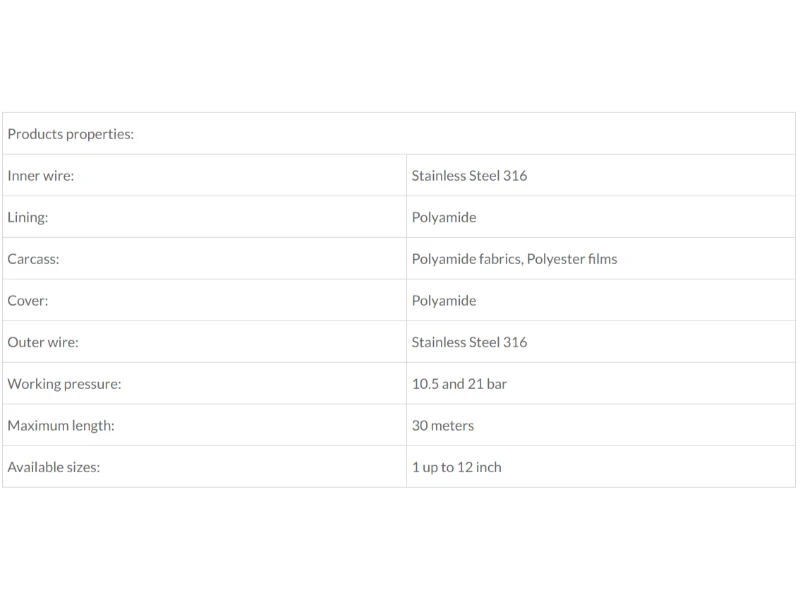

(4)Multi-LNG White:

Multi-LNG White hoses handle frigid conveyants, as low as -196°C.

Engineered for substances like Liquid Nitrogen and LNG, they suit various applications.

Two main variants are available: Multi-LNG White, for LNG bunkering, Ship to Shore transfers, and industrial use. and Multi-LNG White STS, for Ship to Ship operations and LNG Bunker activities.

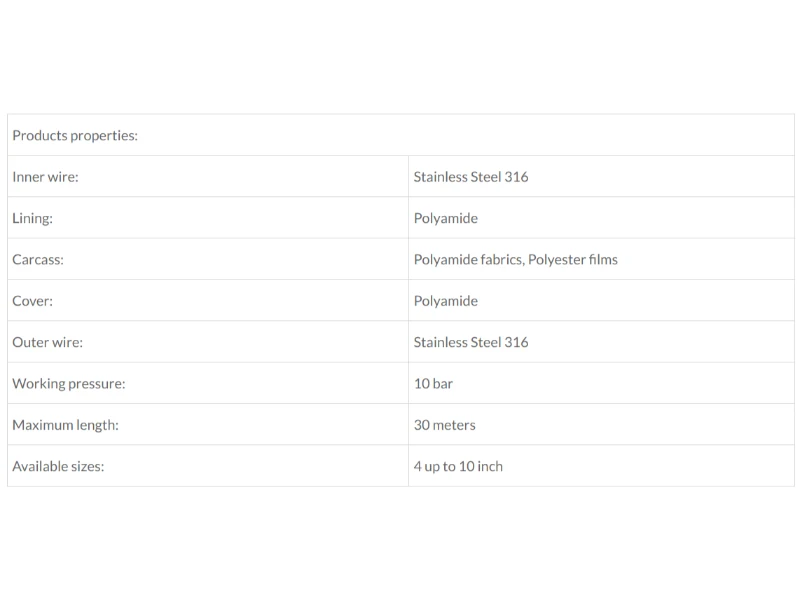

| Products properties: | |

| Inner wire: | Stainless Steel 316 |

| Lining: | Polyamide |

| Carcass: | Polyamide fabrics, Polyester films |

| Cover: | Polyamide |

| Outer wire: | Stainless Steel 316 |

| Working pressure: | 10.5 and 21 bar |

| Maximum length: | 30 meters |

| Available sizes: | 1 up to 12 inch |

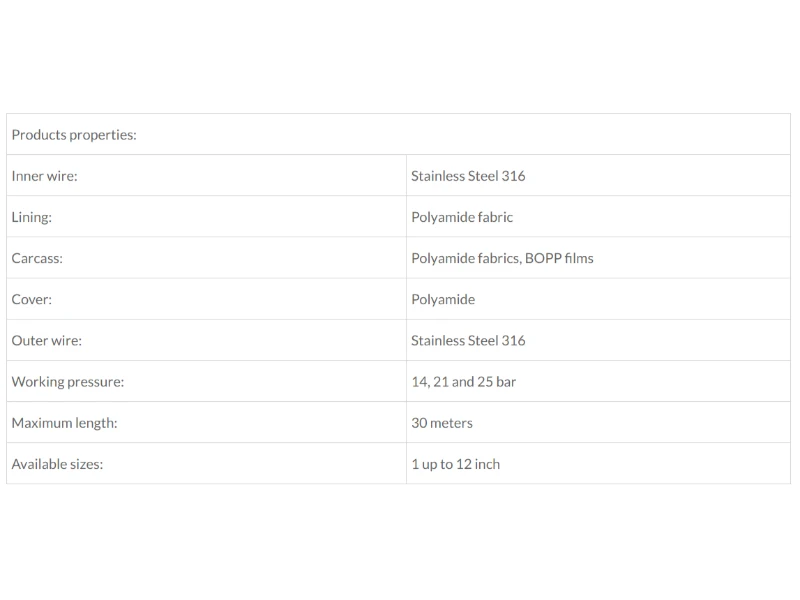

(5)Multi-Chem White:

Multi-Chem White hoses serve submersible needs for Hydrocarbons and chemicals. Outer covers vary with intended chemicals—PP or Hostaflon. Choose from PP, PTFE, or Hostaflon linings. Jerryborg certifies Multi-Chem White hoses to EN 13765, IMO IBC, and PED standards.

| Products properties: | |

| Inner wire: | Stainless Steel 316 |

| Lining: | Polyproylene / PTFE / Hostaflon |

| Carcass: | Polypropylene fabrics, BOPP films |

| Cover: | Polypropelene / Hostaflon |

| Outer wire: | Galvanized Steel or Stainless Steel 316 |

| Working pressure: | 7, 10.5, 14 bar |

| Maximum length: | 30 meters |

| Available sizes: | 1 up to 12 inch |

If you are interested in Jerryborg’s composite hoses products, you can click here to learn more about our products.