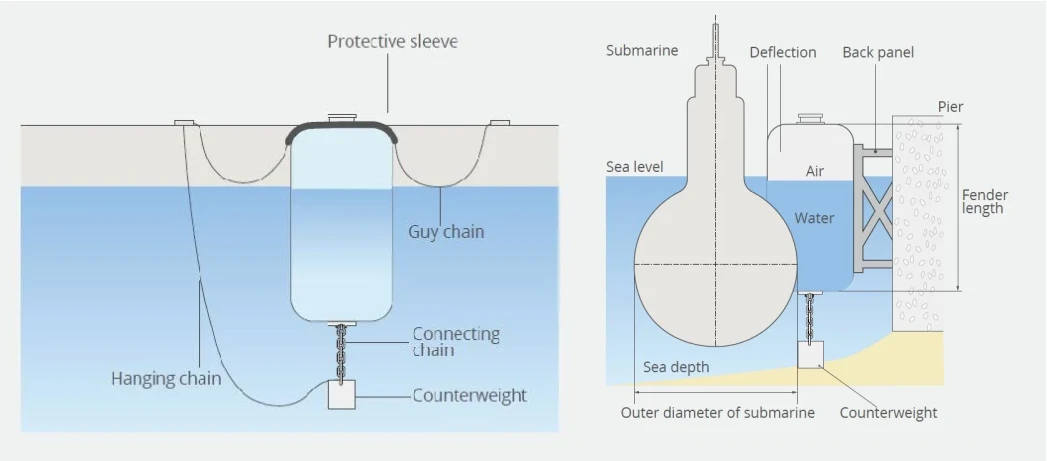

What Are Hydro Pneumatic Fenders?

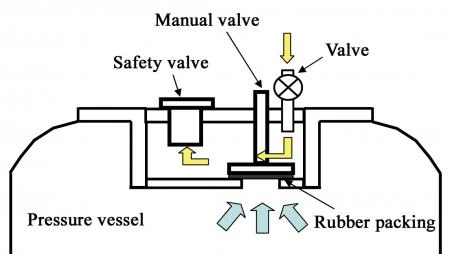

Hydro pneumatic Fenders are specialized variants of pneumatic fenders. These are mainly designed for submarine docking applications. These fenders contain a mixture of water and air, partially filling them. A counterweight at the bottom of the fender ensures it remains vertically afloat in the sea. This design ensures continuous and good protection of the submerged hull. The safety is due to the hydropneumatic fender.

Hydro pneumatic Submarine Fenders have a complex design compared to standard pneumatic fenders. They also require specific installation techniques. The efficiency of Hydropneumatic Fenders depends on factors. These include the air-to-water ratio, the counterweight’s mass, and the initial pressure setting. Jerryborg Marine welcomes your technical specifications for producing hydropneumatic floating fenders. Our produced fenders will be tailored in size and design to meet your operational needs.